ARGONNE, Ill. — The awards recognize the top scientific and technological innovations of the past year as judged by a team of independent experts for R&D magazine. Argonne scientists have won 120 R&D 100 awards since they were first introduced in 1964.

“My sincere congratulations to the winners of this year’s R&D 100 Awards,” said Energy Secretary Ernest Moniz. “The scientists and engineers who developed these award-winning technologies at the cutting-edge facilities across our national labs are keeping Americans at the forefront of the innovation community and assuring our nation’s economic competitiveness and national security.”

This year’s winners from Argonne are:

- Miraj Diamond™ Platform

- Nanocrystalline Diamond (NCD) Technologies Coating

- Nanocomposite Charge Drain Coatings

- The Rhodobacter Membrane Protein Expression System

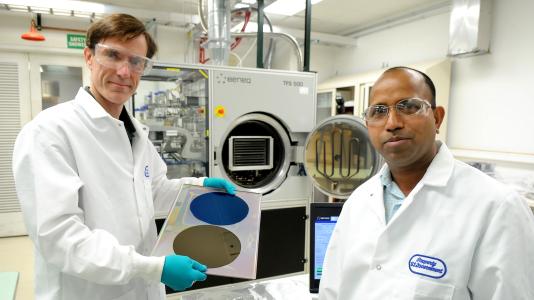

Miraj Diamond™ Platform

The Miraj Diamond™ Platform consists of the combination of two newly developed diamond technologies — low-temperature nanocrystalline diamond deposition technology developed at Argonne’s Center for Nanoscale Materials, and an efficient n-type semiconductor doping process developed by one of Argonne’s commercial partners, AKHAN Technologies. The combination of these breakthroughs allows for a commercially feasible approach to creating cheaper better devices that rely on integrated circuits, which could transform telecommunications, defense and aviation electronics.

Funding for the initial development of the Miraj Diamond™ platform was provided by the U.S. Department of Energy’s Office of Science. For more information about the licensing agreement of the Miraj Diamond™ technology between Argonne and AKHAN Technologies, click here.

Nanocrystalline Diamond Technologies Coating

The NCD Technologies Coating stems from the same vein of research as the Miraj™ Diamond Platform. However, in this application, ultrananocrystalline diamonds are used to create hard, thin, low-friction coatings for tiny drill bits that are less than a hair’s width in size. These drill bits can be used for micromanufacturing, a relatively new form of machining, said co-creator and Argonne nanoscientist Ani Sumant. Micromachines include small mechanical locks used in aviation equipment as well as circuit board printers. These drill bits could also find their way into dentists’ offices for precision work, he said. Sumant’s wins for both the NCD Technologies Coating and the Miraj™ Diamond Platform make him the first Argonne researcher to win two R&D 100 Awards in the same year.

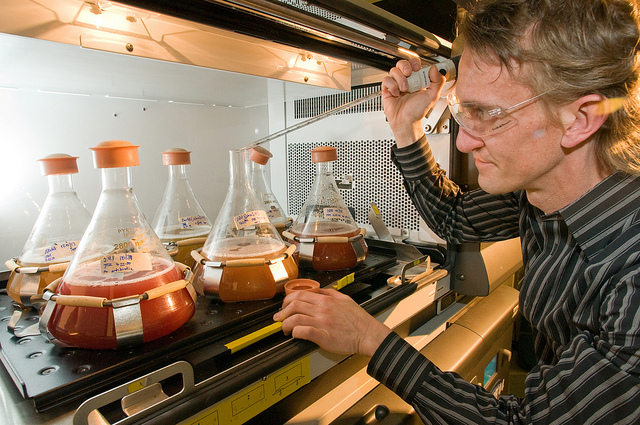

The Rhodobacter Membrane Protein Expression System

The cell membrane serves as the interface between an organism and its environment, and internal membranes in multicellular organisms separate functional compartments within cells. Proteins inserted in these membranes carry out many essential biological processes including uptake of nutrients, excretion of wastes, signal transduction, and response to external stimuli. Unfortunately, structural information for membrane proteins is exceedingly scarce. Membrane proteins are highly unstable in the water-containing environments in which they are typically studied, which is why only about 200 membrane proteins out of more than 15,000 total proteins have been characterized.

While established technology can routinely generate sufficient quantities of soluble protein for structural studies, no general systems exist or are routinely employed which are tailored specifically for the overexpression of membrane proteins. Argonne biologists Philip Laible and Deborah Hanson developed a system that uses photosynthetic bacteria (Rhodobacter) to create much larger amounts of membrane protein than was ever before available, driving down production costs and making studies of membrane proteins easier both in terms of scalability and purification.

Nanocomposite Charge Drain Coatings

Argonne’s work in nanocomposite charge drain coatings represents a significant breakthrough in the laboratory’s efforts to develop microelectromechanical systems, or MEMS. One of the most significant potential obstacles to the creation of these devices lies in the fact that electrons can sometimes become trapped in the substrate. To prevent this from happening, Argonne scientists Anil Mane and Jeffrey Elam used atomic layer deposition to create extremely thin coatings that would enable the material to function more efficiently.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation’s first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America’s scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC for the U.S. Department of Energy’s Office of Science.

The Center for Nanoscale Materials at Argonne National Laboratory is one of the five DOE Nanoscale Science Research Centers (NSRCs), premier national user facilities for interdisciplinary research at the nanoscale, supported by the DOE Office of Science. Together, the NSRCs comprise a suite of complementary facilities that provide researchers with state-of-the-art capabilities to fabricate, process, characterize and model nanoscale materials, and constitute the largest infrastructure investment of the National Nanotechnology Initiative. The NSRCs are located at DOE’s Argonne, Brookhaven, Lawrence Berkeley, Oak Ridge and Sandia and Los Alamos National Laboratories. For more information about the DOE NSRCs, please visit http://nano.energy.gov.