At the U.S. Department of Energy’s (DOE) Argonne National Laboratory, materials scientist Daniel Abraham works to do just that for lithium-ion batteries. These are the kind that power cell phones, laptops and the next generation of plug-in hybrid or all-electric cars. Abraham and his colleagues are working to extend battery life, while simultaneously trying to increase storage capacity.

“In cell phones, you can get away with a battery that lasts only a couple of years,” he said. “For vehicles, you need a battery that lasts 10 to 15 years, which is the typical lifetime of a car.”

To extend batteries’ working lives, researchers need to understand how and why batteries fail.

“I think of it as solving a series of mysteries,” Abraham said. “How did it happen? How can we prevent it from happening again? To find out, we often take apart the battery and examine its contents for clues using an array of diagnostic tools.

As it turns out, there are many ways for batteries to fail.

A lithium-ion battery contains four basic components: a positive cathode, a negative anode, an electrolyte that allows lithium ions to flow between them; and a separator that keeps the electrodes apart to prevent short circuits.

When you charge the battery, the current from the electrical outlet forces lithium ions to move from the cathode to the anode. This converts electrical energy from the outlet into stored chemical energy. When you unplug the battery and begin to use it, the lithium ions flow back to the cathode; the stored chemical energy is converted into a stream of electrons to power the device.

Of course, in a complex system, many things can go wrong.

Both the cathode and anode are composed of tiny particles glued together with a chemical “binder” and painted on over a metallic sheet. Sometimes the binder fails and the composite comes apart; sometimes the entire layer peels off the sheet.

The anode is typically made up of long planes of graphite, called graphene. Lithium ions arrange themselves between the graphene planes, making them expand and contract—and eventually some of the planes can crack. The liquid electrolyte also eats away at the edges of the graphite. Buildup of a protective layer between the electrolyte and the graphite can prevent corrosion, but the layer is built using precious lithium ions, taking them out of circulation and lowering battery performance.

Meanwhile, the cathode is typically made up of lithium-bearing oxide or phosphate particles. The buildup of electrolyte reaction products can create obstacles to ion motion, draining power performance. Or changes in the particles’ crystal structure can siphon away energy during battery operation.

More seriously, in rare cases lithium batteries can catch fire or even explode.

Quality control matters more in lithium-ion batteries than in other battery systems. Battery packs contain individual cells that are electrically linked together. But if one cell is faulty and doesn’t perform as well as the others, it’s more than inefficient: it’s dangerous.

“Say the faulty cell has only half the capacity of the others,” Abraham said. “When I plug in to charge, that one cell will fill up faster than the others, and it begins to overcharge. Remember that charging is just supplying electrical energy into a battery. If I keep adding energy, the electricity has nowhere to go, and it’s transformed into heat. The heat eventually exceeds the flammability threshold of the electrolyte, and the cell bursts into flame.”

Thus, the well publicized recalls of lithium-ion batteries in recent years. Safety is paramount, especially in batteries for cars, and considerable research is directed at improving the intrinsic safety of battery materials.

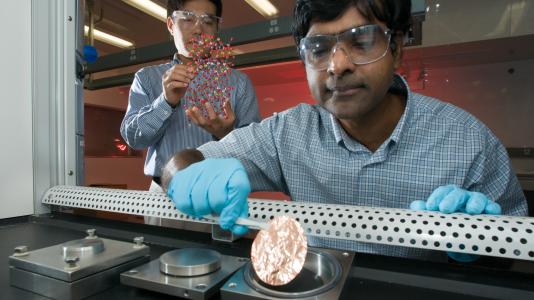

“The arrangement of atoms within the crystal structure plays a role in how the battery performs,” Abraham explained. “What we are doing now is looking at batteries in situ: that is, actually watching the battery as it charges and drains, using powerful X-rays from the Advanced Photon Source and electrons from the Electron Microscopy Center. That’s the cutting edge of battery diagnostics.”

A combination of methods allows researchers to examine every angle. For example, microscopy methods help the team decipher the architecture and composition of battery components, while X-ray techniques allow them to decode the arrangement of individual atoms.

Armed with an understanding of how things work or fail, the scientists set out to find solutions to each problem. Modifying the elemental composition and size of cathode particles can improve energy and power; a pre-made protective layer on graphite can reduce corrosion; altering electrolyte chemistry can make the cell more heat-tolerant; better manufacturing practices can reduce the incidence of electrical shorts.

Now the scientists have a new and hopefully improved battery. Now what? “Obviously, the next step is to test it out,” Abraham said. “But when you want to see how the battery performs over 15 years, you have a problem on your hands: you can’t wait 15 years for the results.”

“Accelerated aging” is a way to simulate the results of 15 years of wear and tear in just a few months or a year. Battery testers charge and drain the cells over and over again at elevated temperatures; the test conditions are carefully chosen to mimic the effect of years of use. Using this method, scientists can cycle through testing, diagnostics and chemistry modifications, changing and re-testing generations of batteries in just a few years.

Abraham leads a team of researchers from Argonne, Lawrence Berkeley, Brookhaven and Oak Ridge national laboratories funded by the Advanced Battery Research program, part of the Vehicle Technologies program of DOE’s Office of Energy Efficiency and Renewable Energy. He also has extensive interactions with researchers from the University of Illinois, University of Rhode Island, Purdue University and Brown University.

To follow Abraham and collaborator Mahalingam Balasubramanian as they run one cathode ingredient through rigorous tests, see Building a Better Battery at the Advanced Photon Source’s news archive.

Editor’s Note: This article is the second in a series of stories that will highlight Argonne’s wide-ranging energy storage research capabilities and technology-development successes.