The U.S. Department of Energy’s (DOE) Argonne National Laboratory is joining lead organization Northern Illinois University in a $2 million project over three years to develop a prototype low-cost system for capturing carbon dioxide (CO2) waste from manufacturing emissions and cleanly converting it into ethanol. Also joining the project are the University of North Texas and Angstrom Advanced Inc.

DOE’s Office of Energy Efficiency and Renewable Energy is funding this project for a three-year period.

“The process resulting from our catalyst would contribute to the circular carbon economy, which entails the reuse of carbon dioxide.” — Di-Jia Liu, a senior chemist in the Chemical Sciences and Engineering division.

“Our long-term vision is for a cleaner and sustainable planet,” said Tao Xu, the project lead and a Chemistry Professor at Northern Illinois University. “If we develop a successful prototype, it will be a step toward a more sustainable future.”

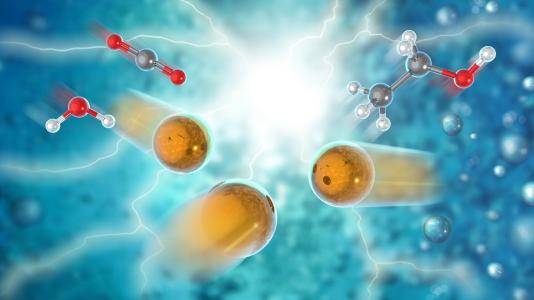

This newly funded project is a natural outgrowth of the discovery of a new electrocatalyst that converts carbon dioxide (CO2) and water into ethanol with very high energy efficiency, high selectivity for the desired final product and low cost. A report on the discovery was published in the July 27, 2020, issue of Nature Energy.

The team’s electrocatalyst consists of atomically dispersed copper on a carbon-powder support. By an electrochemical reaction, this catalyst breaks down CO2 and water molecules and selectively reassembles the broken pieces into ethanol under an external electric field. The electrocatalytic selectivity, or “Faradaic efficiency,” of the process is over 90 percent, much higher than any other reported process. What is more, the catalyst operates stably over extended operation at low voltage.

“The process resulting from our catalyst would contribute to the circular carbon economy, which entails the reuse of carbon dioxide,” said Di-Jia Liu, a senior chemist in Argonne’s Chemical Sciences and Engineering division and a UChicago CASE senior scientist in the Pritzker School of Molecular Engineering, University of Chicago. This process would do so by electrochemically treating the CO2 generated from industrial processes.

“To avoid emission into the atmosphere, the generated CO2 will be trapped by our direct-air capture module containing a metal-organic framework absorbent and will then be supplied to an integrated CO2 low-temperature electrolyzer for conversion to ethanol,” said Shengqian Ma, a professor and the Welch Chair in Chemistry at the University of North Texas and a former Director’s Postdoctoral Fellow at Argonne.

Greenhouse gases from industrial and other human activities are the most significant driver of observed climate change since the mid-20th century, according to the U.S. Environmental Protection Agency. Carbon dioxide makes up 81 percent of U.S. greenhouse gas emissions.

For the prototype, the University of North Texas will spearhead the development of an industrial direct-air CO2 capture module, while Northern Illinois University, Argonne and Angstrom Advanced will develop the electrolyzer system. The goal is to integrate the CO2 capture and conversion components to create a prototype that could be scaled up and used to achieve carbon neutral, or even carbon negative, manufacturing. The technology will be designed to be adaptable to various manufacturing settings, such as ethanol manufacturers, thermal power plants, and steel and cement producers.

“The intent of our prototype will be to intercept CO2 before it’s emitted into the atmosphere and convert it back to fuel,” Xu said. “It’s possible we might even be able to capture more CO2 from the environment than has been emitted through manufacturing processes. Ideally, we would use renewable solar and wind energy to then convert carbon dioxide into ethanol.”

Ethanol is a particularly desirable commodity because it is an ingredient in nearly all U.S. gasoline and is widely used as an intermediate product in the chemical, pharmaceutical and cosmetics industries.

The team of researchers expect to have a prototype developed in three years.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation’s first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America’s scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC for the U.S. Department of Energy’s Office of Science.

The U.S. Department of Energy’s Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit https://energy.gov/science.