In additive-manufactured metals and alloys, these challenges often include significant residual stress, an issue commonly addressed by post-build heat treatments. But this approach can also have undesirable side effects.

Under a partnership between the U.S. Department of Commerce’s National Institute of Standards and Technology (NIST) and the U.S. Department of Energy’s Advanced Photon Source (APS), NIST researchers have examined the AM alloy Inconel 625 (IN625) in an effort to better understand the effects of heat treatment on AM alloy microstructure and phase evolution. Their work was published this past June in Acta Materialia.

A widely used superalloy in the aerospace, marine and nuclear industries where its high strength and corrosion resistance are critical advantages, IN625 has limited machinability, which makes it an attractive candidate for AM, and it also presents a good prototype model system for studying AM alloys.

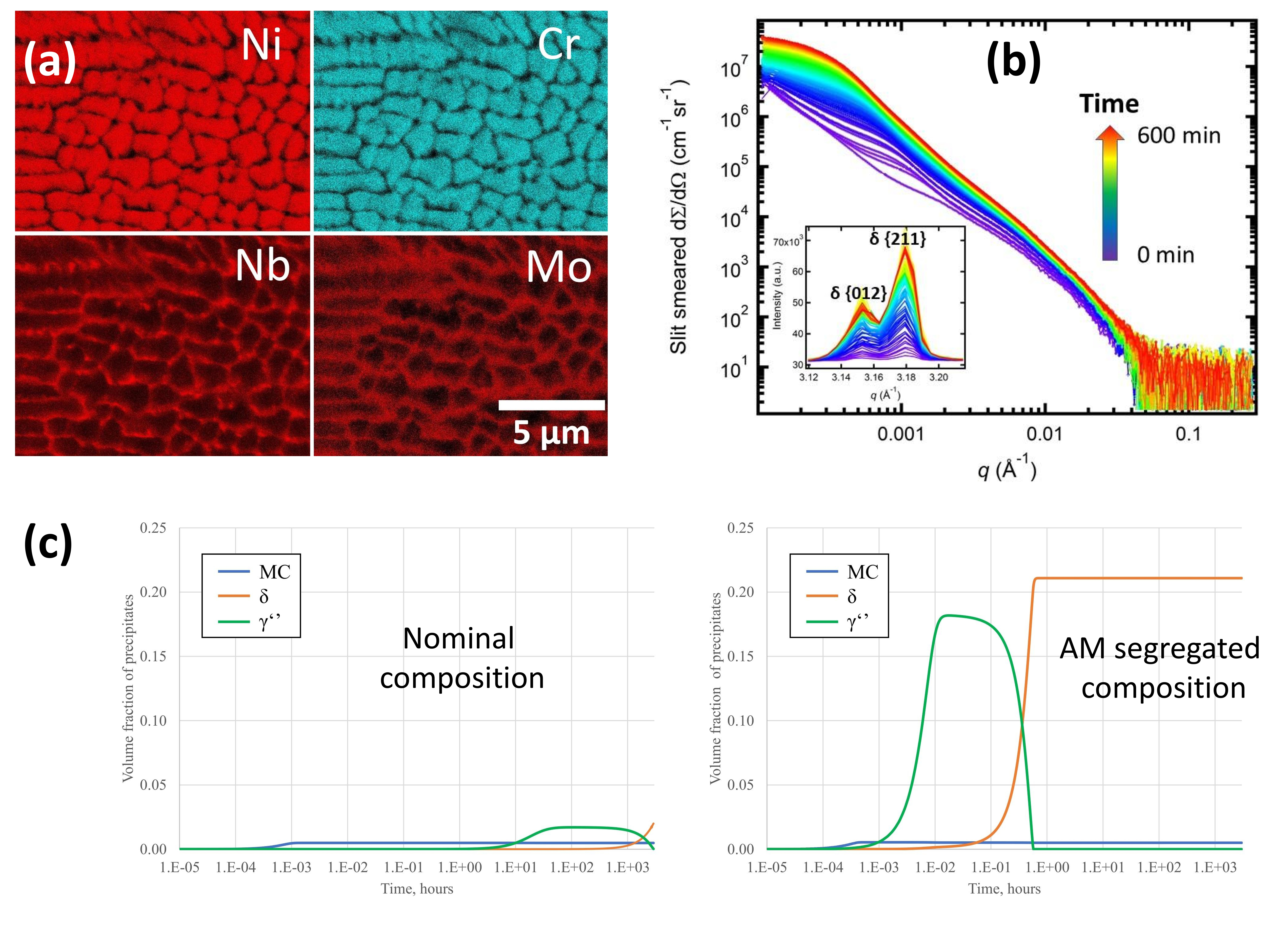

The investigators used electron microscopy and thermodynamic modeling, as well as several X-ray probing techniques to investigate heat-treated IN625 samples on the X-ray Science Division (XSD) 9-ID-C USAXS facility and the XSD 11-BM-B powder diffraction beamline at the APS, an Office of Science User Facility at DOE’s Argonne National Laboratory.

While the AM principle of using a laser or electron beam to build up a material layer by layer is very versatile, it is also volatile and somewhat unpredictable at the microscale. The process involves complex repeated cycles of heating and cooling that inevitably result in a certain degree of microstructural inhomogeneity. One form often seen in AM metals is elemental segregation, which can lead to defect formation during post-build stress-relief heat treatments, necessitating their alleviation by further homogenization heat treatments.

The unexpected side effects of these heat treatments were the focus of the current work, which includes some of the first detailed in situ investigations of the phenomenon.

Ex situ studies of IN625 AM samples using scanning electron microscopy and X-ray diffraction after stress-relief heat treatments reveal the phase profiles and the presence of undesired precipitates in the interdendritic regions, which are known to degrade the material’s mechanical performance.

APS in situ X-ray scattering and diffraction techniques allowed the researchers to observe the actual formation of these precipitates. Across a heat-treatment temperature range of 800° C to 870° C, the precipitates grew very rapidly, beginning less than five minutes after the start of the treatment, suggesting a very low nucleation barrier. Notably, the growth kinetics was at least 100 times faster than that of conventional alloys with almost identical compositions under the same conditions.

Applying a second heat treatment at 1150° C for 1 hour succeeded in removing the precipitates, resulting in a single-phase face-centered cubic structure. However, this second heat treatment promoted grain growth that could possibly weaken the alloy’s mechanical strength. The research team is continuing to explore, in greater detail, the benefits and adverse effects of this homogenization heat treatment.

Although the current study was confined to AM IN625, the investigators note that their general findings are applicable to many other AM alloys, since phenomena such as elemental segregation with undesired precipitate phases are a likely frequent byproduct of AM technology.

Extending the multifaceted approach taken in this work to other AM alloys will lead to a better understanding of their phase evolution in comparison with their wrought counterparts, and ultimately to new strategies to avoid or mitigate microstructural defects in additive-manufactured metal alloys.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation’s first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America’s scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC for the U.S. Department of Energy’s Office of Science.

The U.S. Department of Energy’s Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit https://energy.gov/science.