While researchers have found many materials that help to reduce friction, conventional lubricants often have chemical limitations. A recent analysis at the U.S. Department of Energy’s Argonne National Laboratory has identified the properties of a newer, exceptionally wear-resistant substance that works in a broader range of environments.

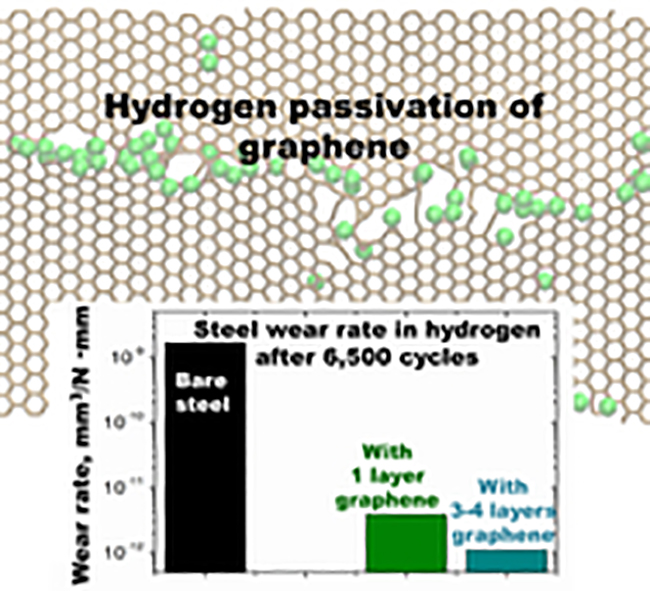

Nanoscientist Anirudha Sumant and his colleagues at Argonne’s Center for Nanoscale Materials and Argonne’s Energy Systems division applied a one-atom-thick layer of graphene, a two-dimensional form of carbon, in between a steel ball and a steel disk. They found that just the single layer of graphene lasted for more than 6,500 “wear cycles,” a dramatic improvement over conventional lubricants like graphite or molybdenum disulfide.

“For comparison,” Sumant said, “conventional lubricants would need about 1,000 layers to last for 1,000 wear cycles. That’s a huge advantage in terms of cost savings with much better performance.”

Graphite has been used as an industrial lubricant for more than 40 years, but not without certain drawbacks, Sumant explained. “Graphite is limited by the fact that it really works only in humid environments. If you have a dry setting, it’s not going to be nearly as effective,” he said.

This limitation arises from the fact that graphite – unlike graphene – has a three-dimensional structure. The water molecules in the moist air create slipperiness by weaving themselves in between graphite’s carbon sheets. When there are not enough water molecules in the air, the material loses its slickness.

Molybdenum disulfide, another common lubricant, has the reverse problem, Sumant said. It works in dry environments but not well in wet ones. “Essentially the challenge is to find a single all-purpose lubricant that works well for mechanical systems, no matter where they are,” he said.

Graphene’s two-dimensional structure gives it a significant advantage. “The material is able to bond directly to the surface of the stainless steel ball, making it so perfectly even that even hydrogen atoms are not able to penetrate it,” said Argonne materials scientist Ali Erdemir, a collaborator on the study who tested graphene-coated steel surfaces in his lab.

Argonne postdoctoral researchers Diana Berman and Sanket Deshmukh also collaborated on the research.

In a previous study in Materials Today, Sumant and his colleagues showed that a few layers of graphene works equally well in humid and dry environments as a solid lubricant, solving the 40-year-old puzzle of finding a flawless solid lubricant. However, the team wanted to go further and test just a single graphene layer.

While doing so in an environment containing molecules of pure hydrogen, they observed a dramatic improvement in graphene’s operational lifetime. When the graphene monolayer eventually starts to wear away, hydrogen atoms leap in to repair the lattice, like stitching a quilt back together. “Hydrogen can only get into the fabric where there is already an opening,” said Subramanian Sankaranarayanan, an Argonne computational scientist and co-author in this study. This means the graphene layer stays intact longer.

Researchers had previously done experiments to understand the mechanical strength of a single sheet of graphene, but the Argonne study is the first to explain the extraordinary wear resistance of one-atom-thick graphene.

An article based on the research, “Extraordinary Macroscale Wear Resistance of One Atom Thick Graphene Layer,” appeared in the Aug. 26 edition of Advanced Functional Materials. A second article, “Graphene: a new emerging lubricant,” appeared in the May edition of Materials Today.

The research made use of the Center for Nanoscale Materials at Argonne and the National Energy Research Scientific Computing Center at Lawrence Berkeley National Laboratory. Both are DOE Office of Science User Facilities.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation’s first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America’s scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC for the U.S. Department of Energy’s Office of Science. For more, visit www.anl.gov.

DOE’s Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.