The future of autonomous materials discovery depends strongly on leveraging the deep scientific knowledge in materials science and chemistry. Microfluidic continuous synthesis is a new way to discover and scale up new materials like organic molecules, polymers, and nanomaterials. While researchers have been developing the method to synthesize components for lithium-ion batteries and nanomaterials, the technology also offers tremendous benefits for large-scale nanomaterials production compared with traditional batch approaches: excellent homogeneity, the capability for full automation through computer-controlled systems, the ability to run processes in difficult conditions, and a scalable architecture that allows researchers to move seamlessly from benchtop to production.

In microfluidic processes, the many parameters that impact product quality must be independently controlled to minimize waste and maximize yield and purity; achieving such control usually requires painstaking trial and error. Continuous, autonomous operation of a self-optimizing reactor system will be a game changer.

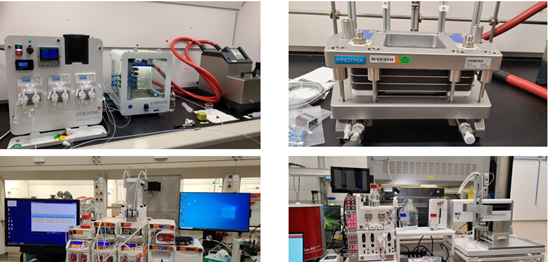

Argonne’s Materials Engineering Research Facility’s (MERF’s) continuous flow chemistry program has successfully demonstrated that continuous flow reactors are a powerful technology platform for hard-to-make materials, offering clear advantages over batch mode in both chemistry discovery and process development and allowing for automation, in-situ and in-operando analysis, and data collection.

For this project, we are upgrading the microfluidic reactors at the MERF for use in an autonomous self-optimizing laboratory module. The initial focus will be on one important area of application: battery electrolyte materials for which the synthesis process is multi-step and the optimization problem is open to innovation. The autonomous laboratory based on continuous flow chemistry will improve productivity and expedite a path to designing, development, synthesis, and scaleup of advanced materials by providing better understanding the process parameters that govern the chemistry.