To help U.S. companies thrive, Argonne researchers connect them to some of the fastest supercomputers in the world. Companies that join this program, funded by the U.S. Department of Energy, look to high-performance computing to spot energy efficiencies. Such efficiencies can cut total production costs and, ultimately, boost U.S. manufacturing and reduce greenhouse gas emissions.

Since 2017, our researchers have partnered with many companies, helping them solve pressing challenges in manufacturing and developing materials. Select partnerships are described below.

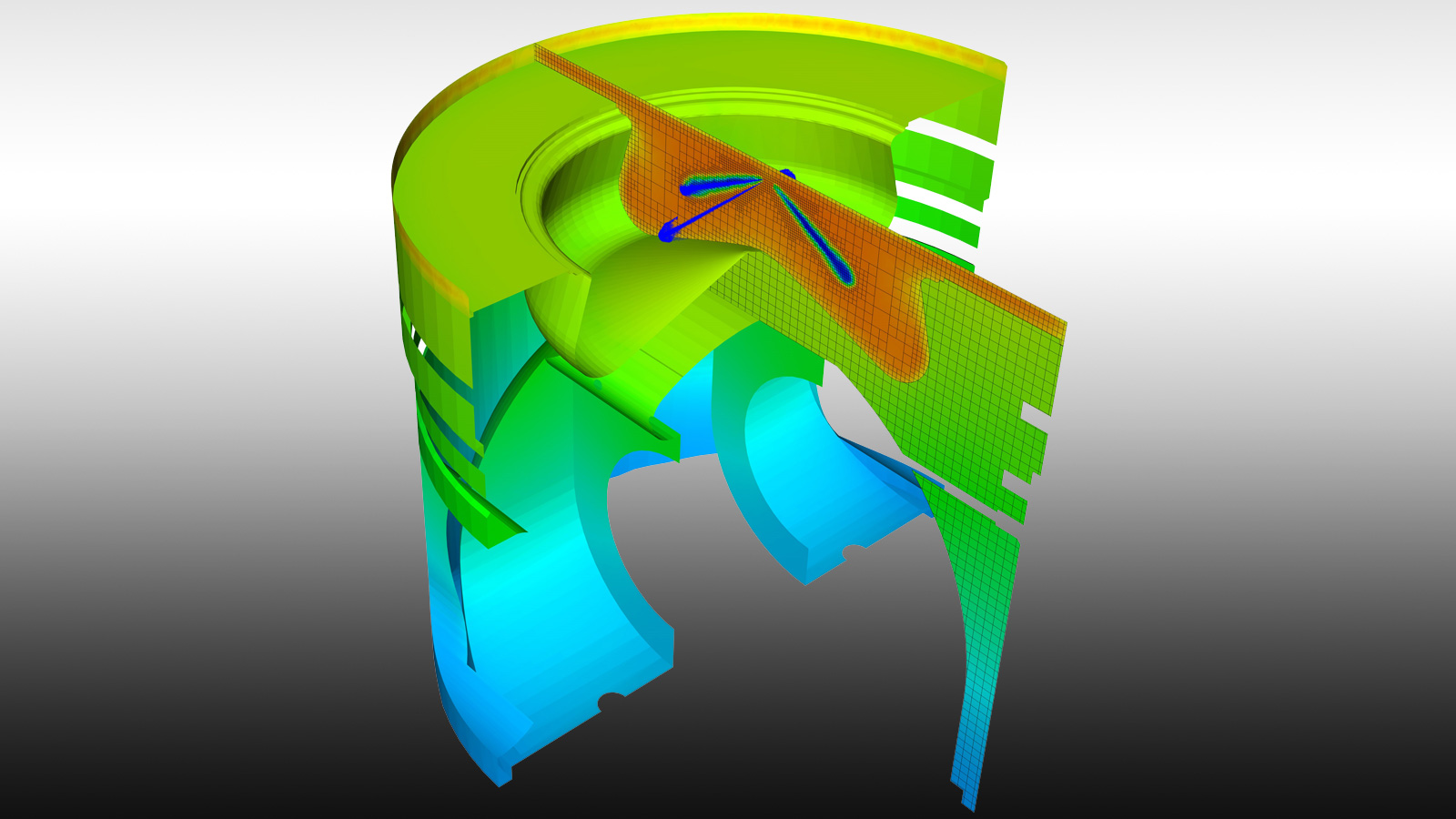

Caterpillar: Improving efficiency, reducing emissions in heavy-duty diesel engines

Argonne engineers worked with Caterpillar Inc., one of the world’s largest manufacturers of construction and mining equipment, to improve efficiency and reduce emissions in their heavy-duty diesel engines.

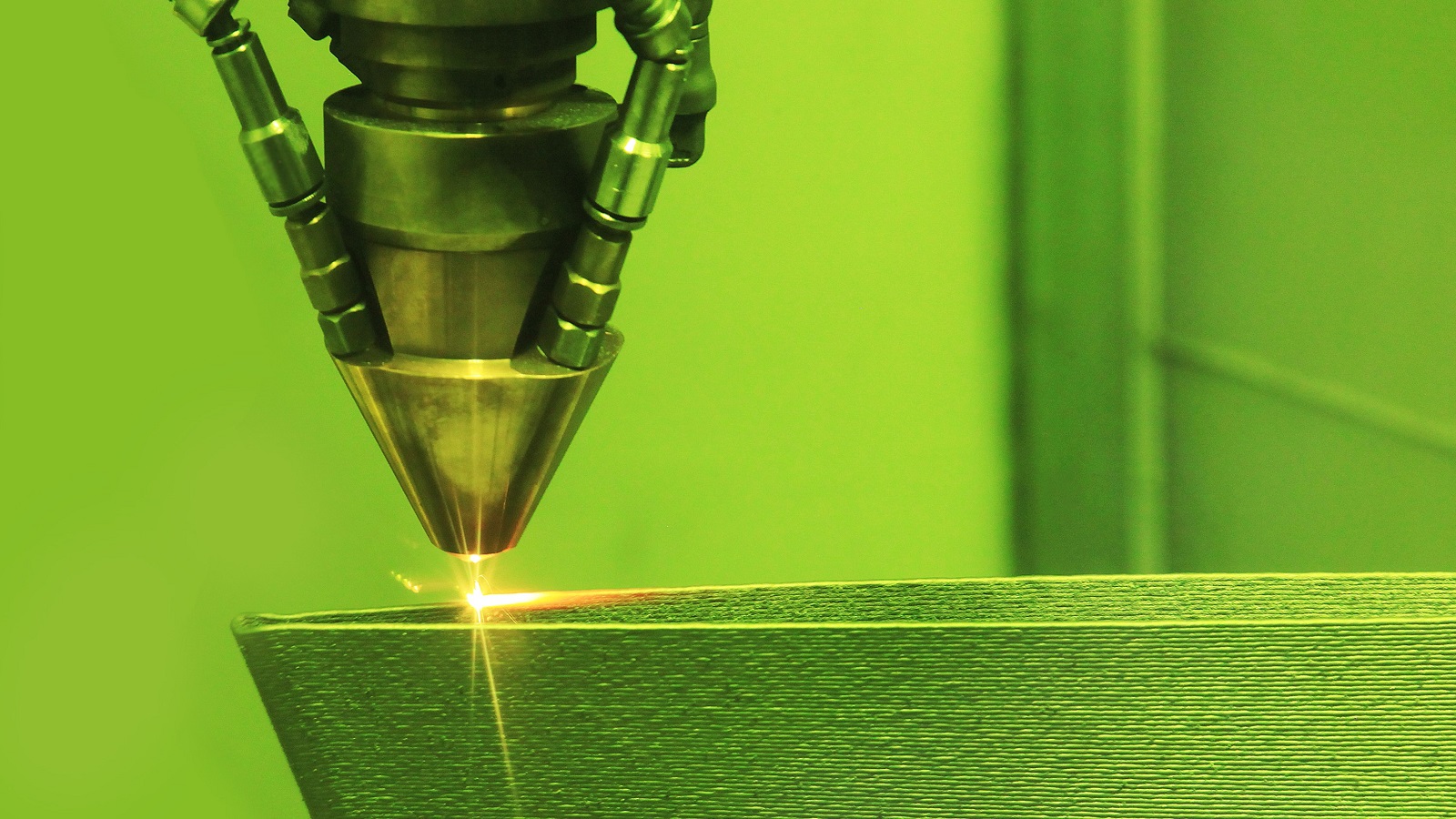

Raytheon: Reducing fuel use in aircraft engines

Raytheon Technologies Research Center is working with Argonne engineers to design a more efficient aircraft engine. They are leveraging recent advances in machine learning and supercomputing to create accurate models that predict air flow and heat transfer inside a gas turbine engine, identifying fine-scale surface effects that could not have been discovered with experimental techniques.

ArcelorMittal: Developing next-generation advanced high strength steels

Argonne experts helped ArcelorMittal develop new technologies and energy-efficient methods for manufacturing defect-free steel slabs. The project not only resulted in less energy use for ArcelorMittal, which runs the largest steel mill in North America, but the new manufacturing process also produced higher-quality cast steel with less greenhouse gas emissions.

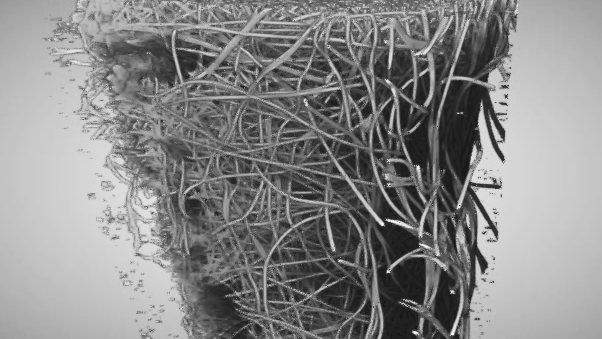

3M: Optimizing fiber manufacturing, cutting costs

Computer scientists at Argonne worked with 3M to use artificial intelligence to optimize the fiber spinning manufacturing process used to produce filters, fabrics, and insulation. The process is also used by 3M to produce face masks and N95 respirators. Fiber manufacturing is an extremely energy intensive process as it relies on compressed air and electrical heating. Using machine learning and computational fluid dynamics, Argonne specialists helped 3M minimize the amount of energy used in producing these materials, reducing the overall cost of production.

For partnership opportunities, contact partners@anl.gov