Operation and maintenance (O&M) costs at commercial nuclear plants are more than three times that of gas turbine plants with these costs accounting for more than 70% of operating expenses. Advanced predictive maintenance practices enabled by AI/ML in combination with a digital twin can provide unique capabilities to automate many of the labor-intensive tasks, the objective being to reduce staffing levels to make existing and advanced reactors more cost competitive.

Equipment Health Monitoring

A basic requirement of an optimum maintenance strategy is the capability to monitor the system in real-time to determine the condition of components. That information can then be used to update the likelihood of component failure that serves as input to a maintenance schedule that is continually adapted given evolving plant conditions.

The current industry-installed capability for on-line diagnosis of component anomalies is limited to anomaly detection using a data-driven digital twin. Nuclear utility experience with these methods has been less than satisfactory. The main issue has to do with reliability with a poor trade-off between sensitivity and false-positive alarms.

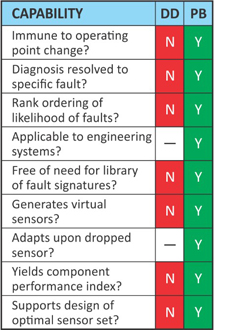

Many of the shortcomings can be remedied by including physics in the diagnostic process. This takes the form of a physics-based digital twin which allows specific faults to be identified given an adequate sensor set. The advantages compared to the data-driven approach are listed in the table.

Component Level

The fault detection and diagnosis problem can be solved using physics-based models constructed for each component in a T-H system to represent component behavior during normal working condition. If a sufficient set of sensor readings is available, the outputs of the component models can be compared against measurement data to detect anomalies in the components using quantitative reasoning.

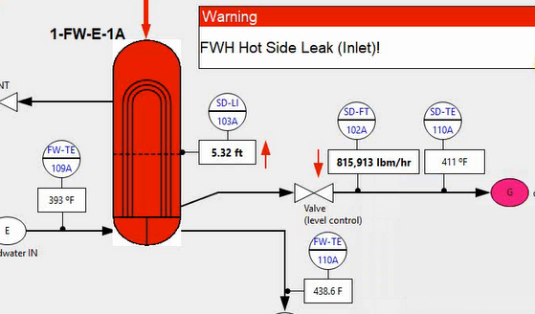

Results from a recent application are described in Single-Phase Heat Exchanger and Feedwater Pump-Motor Set. The application uses a combination of physics-based models, automated reasoning and statistical methods to provide an early indication of degradation in a system of components, much sooner that is achievable by plant personnel and with greater reliability than is achievable by pure data-driven methods.

System-Wide Level

Diagnosis of slow degradation of equipment and sensor calibration using a reasoning process that parallels that of a human, hence rendering an explainable and verifiable diagnosis. Intended as an aid for maintenance optimization and asset management. Facilitates staff reduction though elimination of equipment rounds replacing them with automation of monitoring tasks and their relocation to a remote monitoring center.

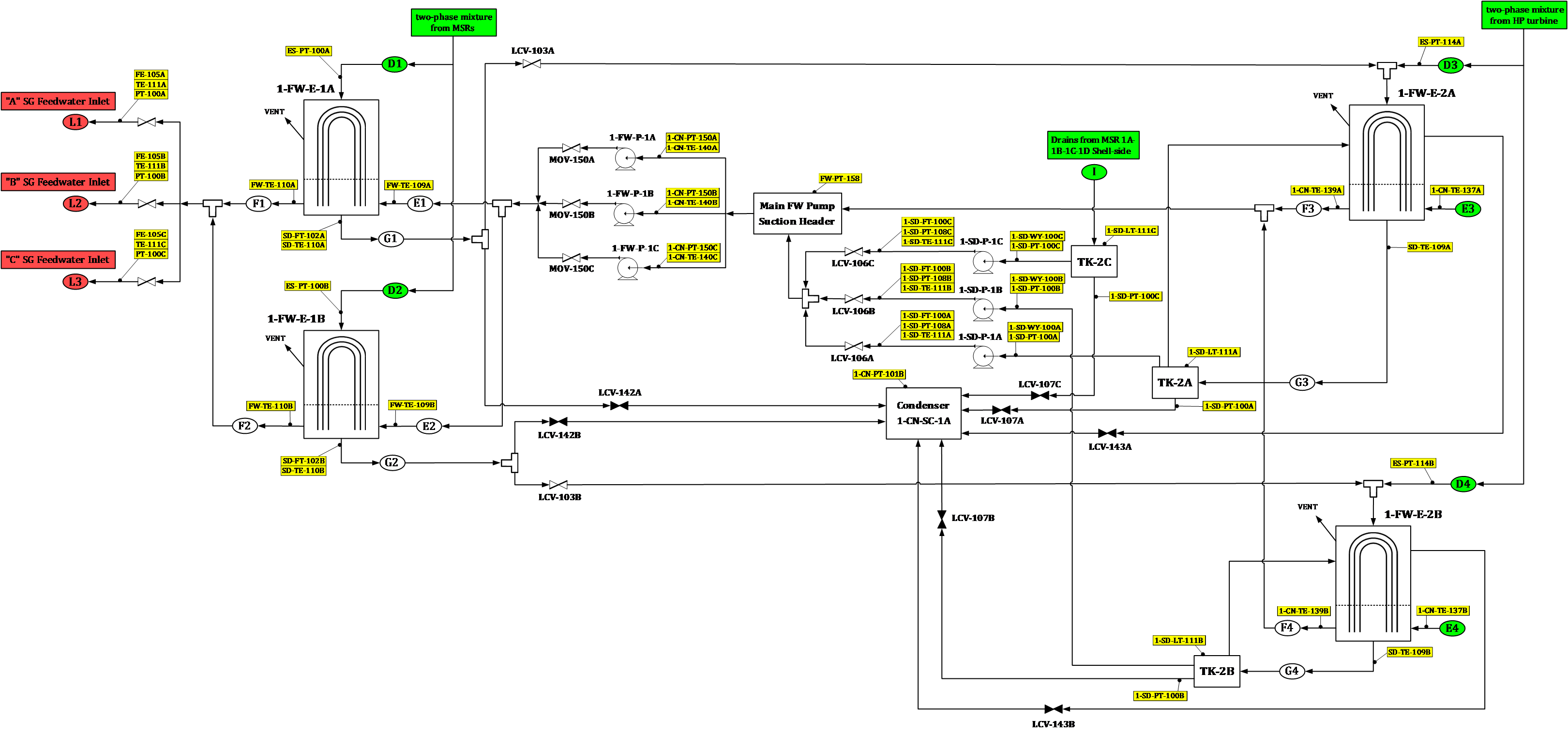

Argonne has developed the software package Parameter-Free Reasoning Operator for Automated Identification and Diagnosis (PRO-AID) that performs real-time monitoring and diagnostics for an engineering system using a form of automated reasoning. The code has been used to analyze the adequacy of sensor set coverage for resolving faults in a system. One such study was for the High-Pressure Feedwater System shown in the figure of a U.S. utility’s PWR.

Prognostic Support for Maintenance Optimization

An optimum maintenance schedule or time for component replacement schedule aims to reduce the cost of maintenance activities. Existing approaches to predictive scheduling of maintenance are based on a generic likelihood of failure for a component without regard for the current component condition or the mechanistic degradation process as it evolves going forward from current time. LPI, Inc. is partnering with Argonne to develop a software package for maintenance optimization. The estimated future reliability of a component is combined with the cost of maintenance or replacement, the savings by deferring scheduled maintenance, and the cost of an in-service failure. The future reliability of a component is derived from PRO-AID diagnostic information combined with an understanding of the mechanisms of component degradation.