When it comes to building a new, more efficient engine for a car or truck, engineers have two avenues of research at their disposal. Either they can conduct real-world experiments, building prototypes of engines or engine components, or they can conduct simulations on a computer.

As the power of high-performance supercomputers, such as those offered by the U.S. Department of Energy’s Argonne National Laboratory, have increased, scientists have begun to steer engine research increasingly towards computation — though not by neglecting experiments.

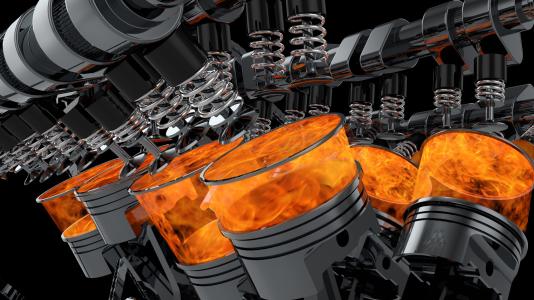

Computational fluid dynamics simulations have begun to transform the playing field of engine design. “Experiments motivate simulations, and simulations motivate experiments,” said Argonne engineer Sibendu Som. “Industry is particularly interested in designs that are informed by both — perhaps conceived on a computer and validated in reality.”

To bring the next generation of engine designs from the idea stage to an actual vehicle, Argonne has partnered with Convergent Science, a Wisconsin-based company that brings computational fluid dynamics expertise to engine design.

Experimentalists and computational scientists have to be able to speak each other’s languages, said Keith Richards, Convergent Science co-owner and vice president. “The end goal is to be able to do everything virtually,” he said. “We’re at a crossroads right now, where we’re moving from experimental to virtual, and the goal of experiments is largely to validate and make numerical simulations more accurate. But it’s critical to do experiments not just to build models up but also for final designs of engines.”

There is heavy demand from industry for next-generation physics-informed engines that combine simulation and experiment, said Don Hillebrand, director of Argonne’s Energy Systems division. “The world is waiting for us to develop the tools needed to design new engine architectures, new concepts, with a finer control over the combustion process. If we can continue to make the progress we’ve achieved over the last ten years, I think society and the environment will continue to reap large rewards,” he said.

The benefit of a partnership between a company like Convergent Science and a national laboratory like Argonne is that laboratories have access to technology and funding that private companies are often unable to obtain on their own. For Convergent Science in particular, access to Argonne’s computational resources made it possible to test their software on large numbers of cores and to work on improving the scalability for clients who want to run highly parallel simulations. Getting access to these types of resources from day one provides a leg up for partners.

The future of engine design is likely to embrace ever more refined simulation methodologies. There may always be the need for some form of experiment, said Argonne engineer Doug Longman, but as computing moves into the Exascale era, there is an opportunity for companies like Convergent Science to have a view of engines they have never had before.