We all want the same things for our vehicles – for them to run smoother, faster, and more efficiently, all with lower cost and emissions. To push these parameters to their peak, researchers at the U.S. Department of Energy’s Argonne National Laboratory are reimagining engines and fuels as a system.

In partnership with Ford Motor Company and Fiat Chrysler Automobiles (FCA US LLC), researchers in Argonne’s Center for Transportation Research have identified an approach for raising efficiency and fuel economy of light-duty vehicles by blending natural gas and gasoline in a dual-fuel engine.

Dual-fuel engines, unlike bi-fuel engines, can operate on two fuel sources simultaneously. In this project, researchers explored dual-fuel concepts in order to leverage the advantages natural gas and gasoline offer, such as natural gas’s high knock resistance relative to gasoline, or gasoline’s ability to burn faster.

“The theory was that you could get some efficiency benefits from blending fuels in this way,” said Argonne engineer and project director Thomas Wallner.

A cornerstone of this approach is the direct injection (DI) of compressed natural gas (CNG) to minimize power density losses and make combustion more efficient.

“This project has successfully demonstrated that CNG direct injection can allow further optimization of CNG-fueled engines by yielding improved efficiency, lower GHG emissions, and higher specific power. These benefits are expected to make CNG DI an attractive technology for future alternative fuel vehicles,” said Chris Cowland, Director of Advanced and SRT Powertrain Engineering at FCA US LLC.

To develop CNG direct injection strategies, researchers used Argonne’s Advanced Photon Source (APS), a high-energy X-ray source, to characterize the behavior of natural gas when injected into a chamber. They applied the measurements from the APS to validate computational fluid dynamics (CFD) models of the behavior expected from the CNG DI spray events.

“We used CFD tools to first understand how the air-fuel mixture forms, and then to optimize injection strategies by altering conditions like the position of the injector, the timing for injection, the ratio of air-to-fuel, etc.” said Argonne mechanical engineer Riccardo Scarcelli.

The Science of Advanced Fuel Technology

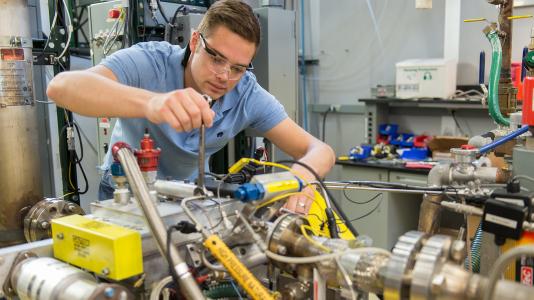

Wallner, Scarcelli, and their colleagues then tested their optimized approach on a single-cylinder research engine to see whether it would yield significant efficiency benefits.

“The experimental findings confirmed that, on the engine level, mixing natural gas and gasoline can be more efficient compared to running on one fuel or the other,” Wallner said.

Researchers took this study a step further by using Argonne’s Autonomie tool, a computational vehicle system simulation tool for vehicle energy consumption and performance analysis, to predict whether vehicles that adopted this approach could expect greater performance and cost savings.

The tool predicted that using the new approach, drivers could break even on cost as soon as 19 months into ownership, depending on the technology’s initial cost. Researchers also found that their approach could increase the power density of light-duty engines by 10% or more, increase efficiency by up to 15%, and reduce petroleum consumption by over 50%, when compared to baseline gasoline engines.

“The project ultimately succeeded in all of its goals, and has added science-based knowledge that can further advance alternative fuel engines,” Wallner said.

The project was funded by DOE’s Vehicle Technologies Office within the Office of Energy Efficiency & Renewable Energy. It employed resources of the Advanced Photon Source, a DOE Office of Science User Facility.