The National Electric Vehicle Infrastructure (NEVI) Program is working towards establishing a comprehensive network comprising of 500,000 electric vehicle charging stations along designated alternative fuel corridors. Through the NEVI Program, individual states will receive dedicated funding to strategically deploy electric vehicle charging infrastructure, fostering an interconnected network that facilitates data collection, ensures accessibility, and enhances overall reliability (NEVI - Environment - FHWA (dot.gov)).

With the implementation of the NEVI Program, there arises a demand for both AC and DC chargers. To enable DC charging, a supply equipment communication controller (SECC) must be implemented in the DC charger. The SECC acts as a bridge between the DC charger power electronics and the electric vehicle’s battery management system implementing high level communication via the HomePlug GreenPHY (HPGP) power line communication (PLC) standard. The Argonne SpEC module can be configured as the main controller of an AC or DC charger.

Custom firmware has been written to support the following standardized communication protocols:

- ISO-15118-20

- ISO-15118-2

- DIN 70121

- SAE J2847/2

The Argonne SpEC module is also capable of digitally interfacing with all Tesla models via the Tesla proprietary CAN protocol via Single-Wire CAN (SWCAN) over the control pilot.

In addition to electric vehicle supply equipment (EVSE) to plug-in electric vehicle (PEV) communication, the SECC also supports OCPP 1.6J for charger to charge station management system communication. This implementation has been self-certified utilizing the OCA 1.6J OCTT.

Features

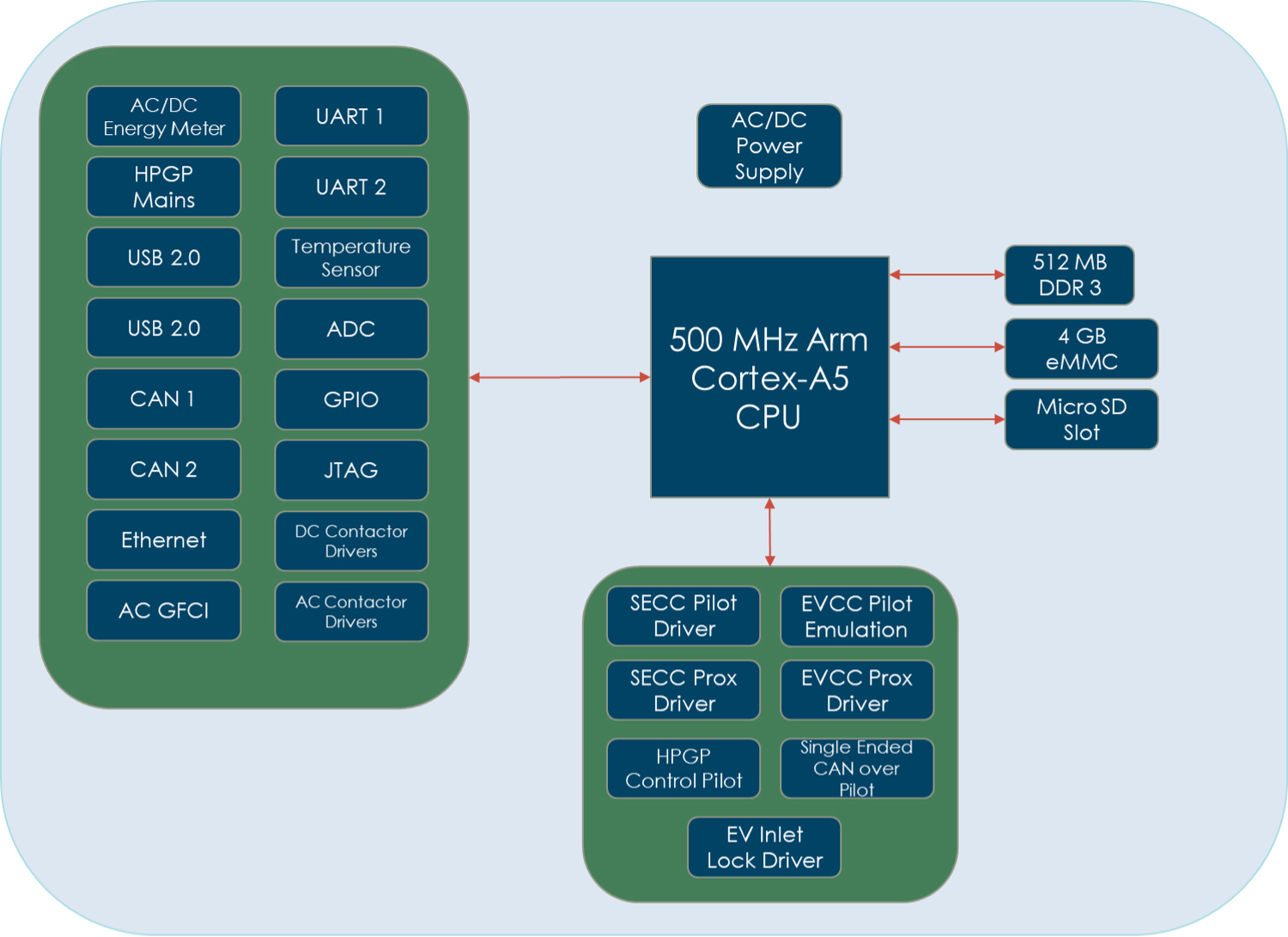

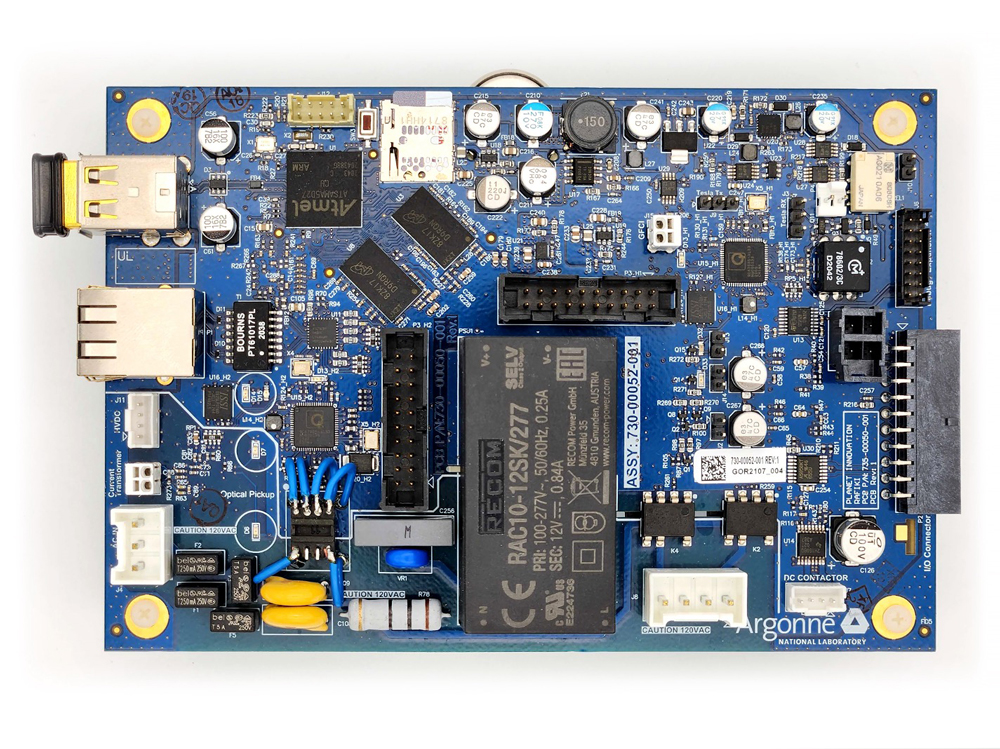

The SpEC module can be configured as both an SECC or EVCC. Most applications to date have focused on the SECC application (both AC and DC). The controller board is based on a 500 MHz ARM Cortex-A5 CPU. The SpEC module supports the latest Linux kernels and distributions. In addition to HPGP over the pilot, the SpEC module also supports PLC over the AC mains with a 2nd dedicated HPGP circuit. The SpEC module has all of the analog interfaces to support both SECC and EVCC deployment for both AC and DC charging. The SpEC module supports CAN, I2C, SPI, USB, SWCAN and Serial communications. The SpEC module also has a built-in AC/DC Energy meter. The controller board natively supports Ethernet communication and all other forms of IP based communication via USB adapters (Wi-Fi, Cellular, etc.).