- ANL-IN-04-076 & ANL-IN-08-087 entitled “MANGANESE OXIDE COMPOSITE ELECTRODES FOR LITHIUM BATTERIES”

- ANL-IN-17-037

- ANL-IN-18-140

Technology Overview

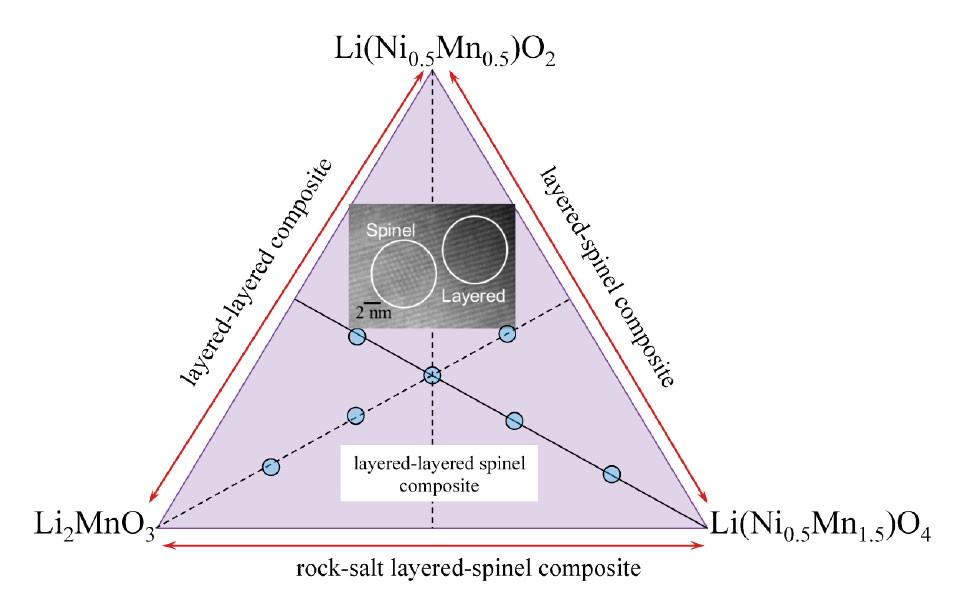

Argonne’s family of manganese and lithium rich materials includes a range of cathode structures, including layered-type structures, spinel-type structures, rocksalt-type structures, and combinations thereof. For example, “layered-layered-spinel” materials with high-rate and stable voltage that are composed of lithium manganese nickel oxides have been discovered and can be used to replace high-energy multi- component “layered-layered” type or single-phase high-rate spinel-type structures for lithium cells and batteries.

See Surface structures, treatments and coatings for high-voltage lithium metal oxide electrodes for complementary surface treatment and coating technologies.

Benefits

- These new material compositions provide substantially higher capacities than state-of-the-art layered lithium/cobalt/nickel/oxide materials, such as nickel-manganese-cobalt (NMC).

- Due to the spinel component, these cathodes are endowed with high power where they can be charged and discharged rapidly.

- The multi-component nature of these materials can be optimized in the phase space in the figure according to the manufacturer’s needs.

- Manganese is less expensive to use and more chemically benign than cobalt or nickel. Either low-cost elements and/or other elements may be doped into the structure to provide better performance, at a lower cost, as needed.

Applications and Industries

Electrodes used in batteries for:

- Electric and plug-in hybrid electric vehicles,

- Stationary energy storage systems,

- Portable electronic devices,

- Medical devices, and

- Space, aeronautical, and defense-related devices.

Developmental Stage

Ready for commercialization.