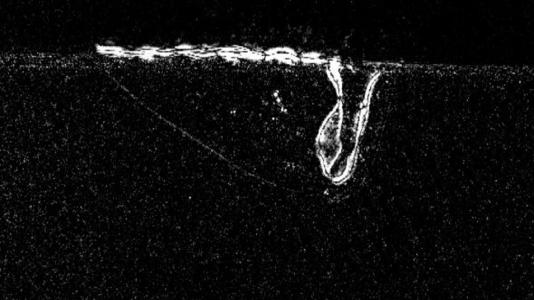

Technology available for licensing: Modern manufacturing, research, and development systems often depend on ultra-high vacuum (UHV) conditions for precise, repeatable environmental control. The components that provide this condition are engineered from stainless steel or other robust, vacuum-compatible materials, but users frequently require linear and rotational degrees of freedom for alignment and manipulation of components being processed or evaluated inside of the UHV system. Standard “bellows” that provide coupling between fixed components do not allow for rotational flexibility, and users are often required to add expensive, custom in-vacuum motion systems to meet their processing needs.

Argonne’s unique bellows design provides added flexibility at a low cost to users requiring UHV conditions. The Argonne solution allows for rotational alignment between system components to reduce or eliminate the need for mechanical manipulation provided by expensive, customized components. The invention can benefit “clean” production environments, including semiconductor manufacturing, synchrotrons or other research systems, precision optics, or other general vacuum or pressurized systems.

Benefits

- Compatibility with standard UHV components

- Replaces expensive in-vacuum motion systems

- Provides design and alignment flexibility

- Maintains vacuum integrity

Applications and Industries

- Semiconductor manufacturing

- Synchrotron & Free-Electron Laser (FEL) light source facilities

- Research systems

- Optical systems

- Vacuum systems requiring rotational alignment or manipulation

- Liquid and gas handling systems