- Precise Application of Transparent Conductive Oxide Coatings for Flat Panel Displays and Photovoltaic Cells (ANL-IN-06-076 and ANL-IN-09-080)

The Invention

Argonne has developed new thin-film, transparent conducting oxide (TCO) coatings for large panel displays and photovoltaic (PV) cells.

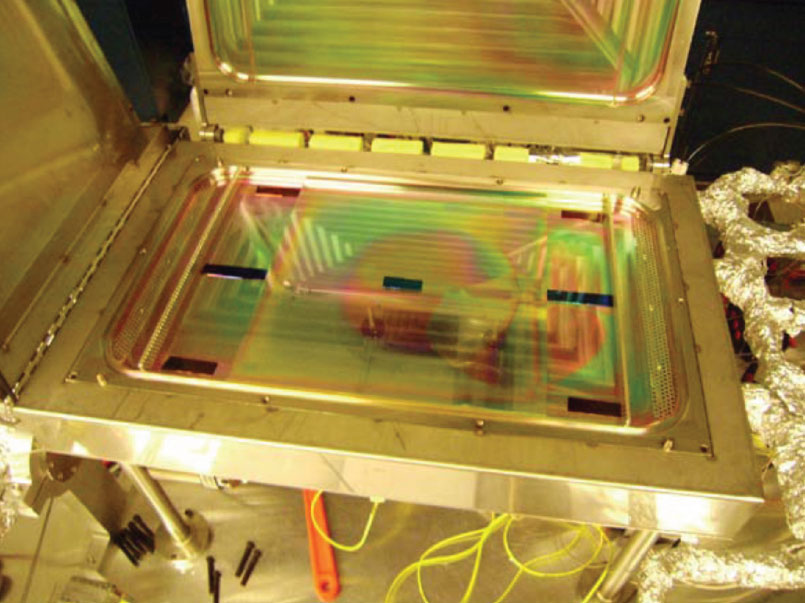

These new TCO coatings are deposited using atomic layer deposition (ALD). ALD employs gaseous precursors to make thin films with thicknesses from atomic mono layer to micron dimensions. This process enables atomic-level control over film thickness and composition, and eliminates line-of-sight or constant-exposure constraints which limit conventional film deposition processes.

Argonne has scaled up the ALD process and successfully demonstrated conformal coating of ITO (Indium Tin Oxide) TCO over 3D nano- and micro-structures at this scale.

Benefits

- Improves flat-panel performance due to thinner, more transparent conductive coatings;

- Reduces materials consumption and expense due to improved coating precision;

- Provides uniform coating of complex, 3D nano-structures such as electrodes for next-generation PV cells;

- Eliminates line-of-sight or constant-exposure constraints which limit conventional film deposition processes; and

- Reduces product rejection resulting from defect free coatings.

Applications and Industries

- Photovoltaics

- Electronics

Developmental Stage

Proof of concept. The production cost analysis showing advantages over state-of-the-art manufacturing has not yet been completed by Argonne. While the coating process has been demonstrated at scale, the performance of a flat panel display or PV cell has not been physically demonstrated in a full scale device.