Devices and films made of thermochromic V02 nanocrystals promises for many applications and potential technological breakthroughs, such as energy efficiency smart windows, infrared laser protection, infrared camera and so forth.

Smart windows made of V02 nanoparticles have readily demonstrated significantly enhanced solar-heat modulation capability in response to temperature variation (approximately twice the capability as compared to traditional thin film counterparts). However, commercial scale manufacturing of high-quality, property-controlled V02 nanoparticles has not been achieved due to conventional batch processing techniques. These techniques cannot precisely control the size, shape and surface properties in a scaled process, which is largely due to its limited capability of controlling heat and mass transfer in a large batch chemical reactor.

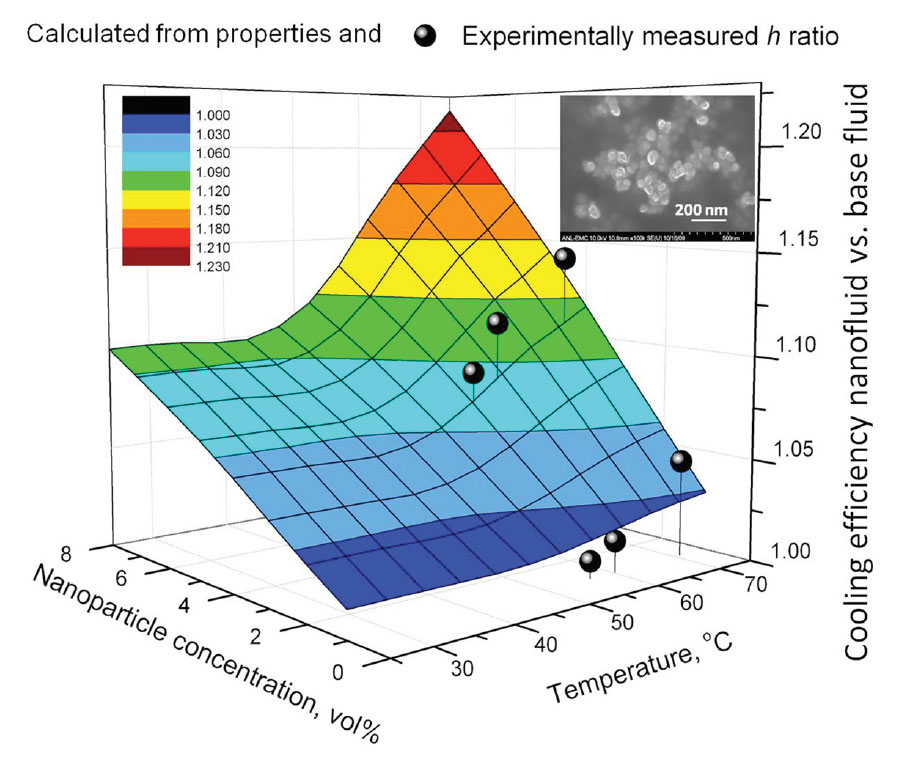

This Argonne invention comprises a new continuous flow synthesis to massively synthesize V02 nanoparticles/rods (B or M phases). This is a solution-phase based hydrothermal, or solvo-thermal synthesis approach that uses a continuous flow micro-reactor. By using a continuous micro-reactor, heat and mass transfer can be precisely controlled and the synthesis reaction can be conducted in an extended range of temperatures and pressures. This is particularly useful and suited to hydrothermal synthesis of high-quality V02 (M) nanocrystals because the phase selection of this material, from its other structures V02 (A, B, R) and phases (e.g. V6013 and V409) depend closely on temperature. At the same time, the reaction can be conducted in a relatively easy, flexible and safe mode (i.e., a limited amount of chemical reagents are heated at a time). This results in well-controlled, nano-particulate products with unique and enhanced infrared (heat) manipulation properties.

Furthermore, this process is scalable and capable of stably manufacturing high-quality V02 nanoparticles or nanorods in specific, and a spectrum of other nano-scale materials in general, at the kilo/day level.