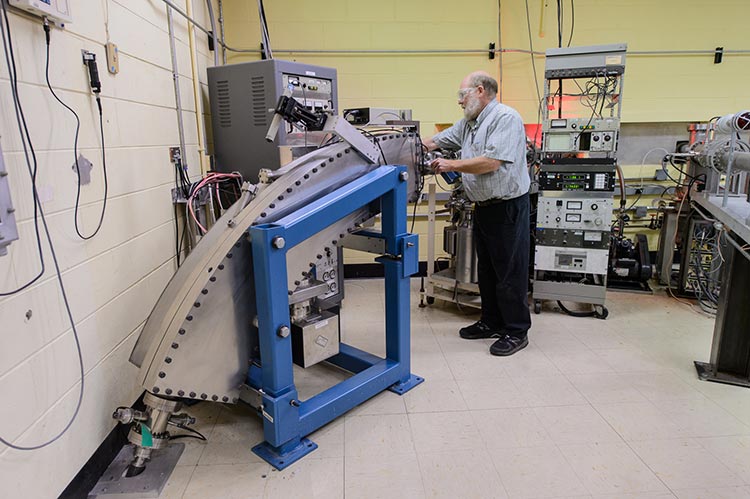

An NEC Implanter with terminal voltage up to 500 keV and a 911 Danfysik ion source supply the IVEM’s ions for in situ irradiation.

Available Elements and Gases

Available ion masses include hydrogen, the inert gases, and many elements from Al to Au. A common ion for in situ damage studies is Kr with double charge to achieve 1 MeV energy with 99% transmittal through a typical TEM thickness of 100 nm in Fe. Ion energies from 50 to 500 keV are possible for singly charged ions.

Due to limitations on source lifetime, doses greater than about 10 dpa require using inert gas ions.

Flux

Ion flux is measured to an accuracy of ±10% by annular Faraday cup (FC) located within the IVEM at 4 cm from the TEM sample. The ion beam is weakly rastered to be uniform over the total area of annular FC and pass-through aperture, which produces a highly uniform incident beam 1.5 mm in diameter on the sample centered on the position of the electron beam at the sample.

Ion flux ranges from 1010 to 1012 ions/cm2sec (corresponding to 10-5 to 10-3 dpa/sec for 1 MeV Kr incident on Fe), with a total fluence accuracy of ±10%. Depending on the amount of microscopy performed at intermediate doses, a total dose of 50 dpa can be achieved in about a day.

Use SRIM program to estimate ion damage/implantation for your experiment. Use K-P quick calculation and average threshold energy for your material to estimate dpa values.

Videos illustrating dislocation motion with in situ straining and without ion irradiation (left panel) and with ion irradiation (right panel). Material is 304 stainless steel held in situ at 400°C. Irradiation was with 1 MeV Kr ions to dose of 3x1013 ions/cm2. Note the pinning of dislocations by irradiation defects impedes motion in the irradiated material, which results in its embrittlement.

J. Kacher, I. M. Robertson (U. Illinois at Urbana-Champaign), “Quasi-four-dimensional analysis of dislocation interactions with grain boundaries in 304 stainless steel,” Acta Materialia 60 (2012) 6657.

M. Briceño et al. (U. Illinois at Urbana-Champaign), “Effect of ion irradiation-produced defects on the mobility of dislocations in 304 stainless steel,” J. Nucl. Mater. 409 (2011) 18.

(size bar is 100 nm and is 1/3 the width of the ion irradiated panel)

Videos courtesy of: Ian M. Robertson (IMR) Research Group, Dept. of Materials Science and Engineering, University of Illinois at Urbana-Champaign