- Acoustic Building Infiltration Measurement System/Sonic Leak Quantifier (SonicLQ) (ANL-IN-14-001)

Building infiltration – the uncontrolled leakage of air in and out of a building envelope – accounts for a significant portion of the heating and cooling energy for buildings and is estimated to account for nearly 4% of all energy use in the United States. Infiltration can be measured on residential and small commercial buildings using whole building pressurization (blower door) testing after construction is complete, but there is no affordable method for testing larger buildings while under construction or when construction is complete. While building energy codes are changing to set maximum limits of infiltration on new construction, the code changes will not require testing of new commercial construction because of the difficulty involved.

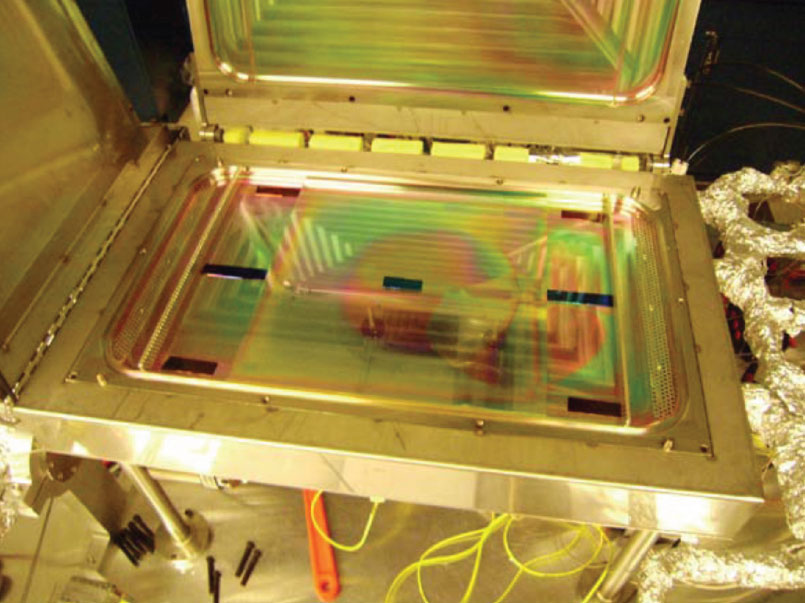

The Acoustic Building Infiltration Measurement System (ABIMS) uses acoustic methods to locate and quantify leak locations on building envelopes. It can be used for buildings of all sizes and can be used while the envelope is still under construction. The technology should allow future commercial building energy code to require infiltration testing on commercial building and allow for affordable quantification of the energy savings benefits of weatherization and infiltration sealing of commercial buildings.

The ABIMS system is being commercialized under the name Sonic Leak Quantifier or SonicLQ. SonicLQ recently won funding from the DOE Lab Corp program to help support commercialization of the technology.