- Coating Active Materials for Applications in Electrochemical Devices (ANL-IN-09-043)

The Invention

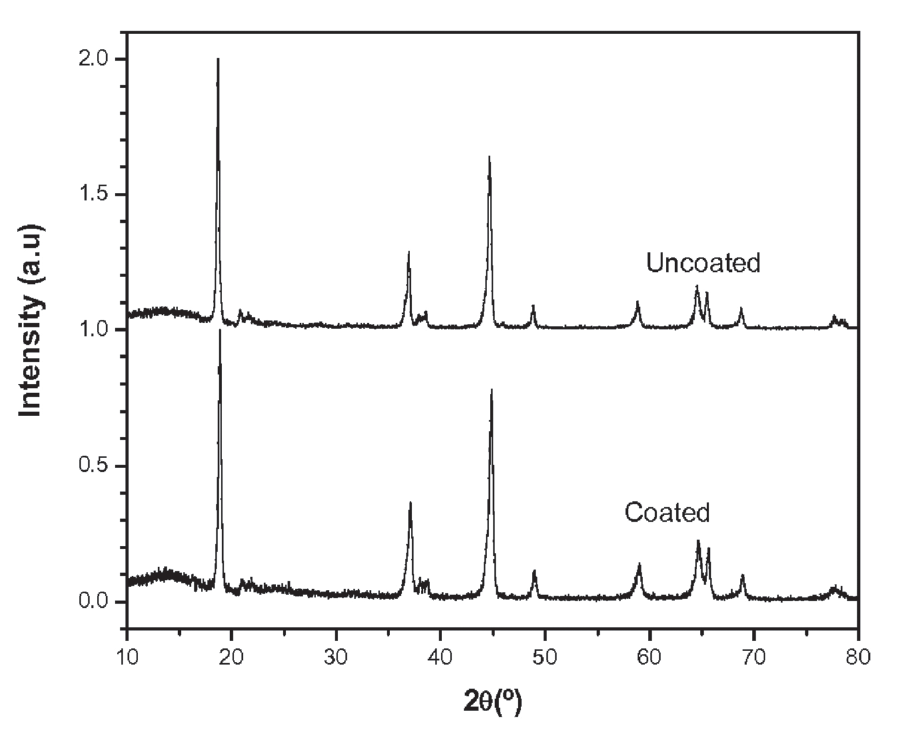

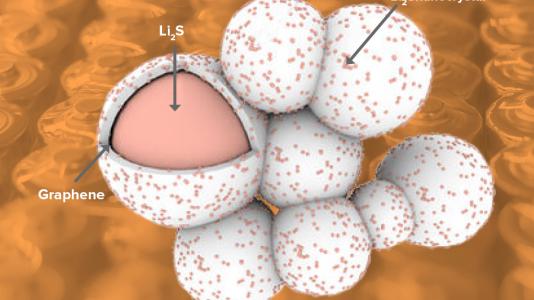

A process that includes suspending/dissolving an electro-active material and a carbon precursor in a solvent; and then depositing the carbon precursor on the electro-active material to form a carbon-coated electro-active material.

The method avoids the high temperature, pressure and manufacturing extremes of conventional chemical vapor deposition and other pyrolysis methods of preparation. When carbon-coated metal oxides (for electro-active materials) are prepared, the metal oxide often reduces to the metal species. Argonne’s method can produce carbon-coated metal oxides without the problems associated with reductions. The carbon precursor can be graphene, graphene oxide, carbon nanotubes, their derivatives or a combination of any two or more such carbon precursors.

Benefits

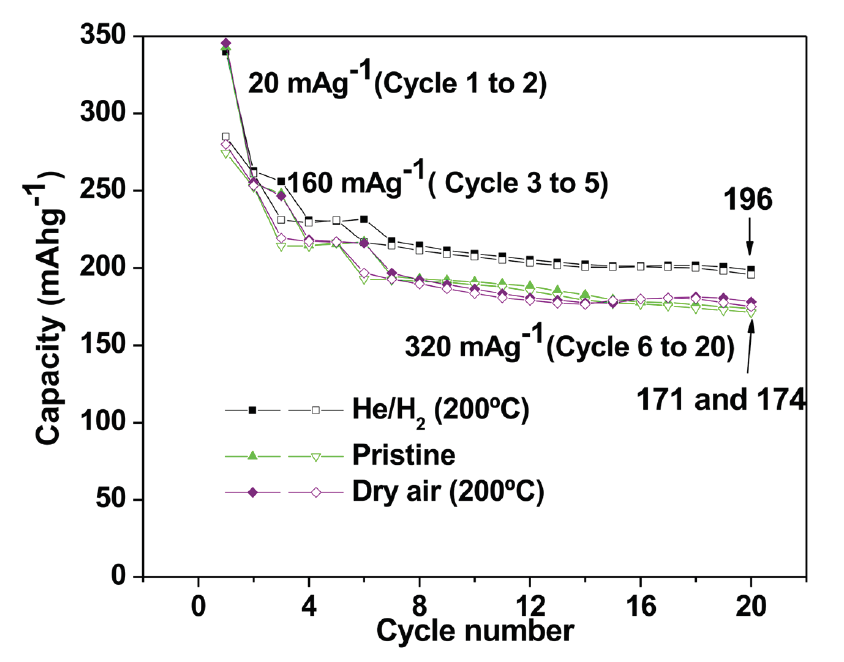

- Carbon-coated materials can be charged and discharged faster than non-coated materials.

- Using this method, the metal oxide will not reduce to the metal species when coated with carbon.

- Carbon-coated cathode materials have improved electronic conductivity.

- With its high capacity and high current rate, carbon-coated materials are ideal for use in lithium batteries for plug-in and electric vehicles.

Applications and Industries

Coatings for electrodes used in batteries for

- Electric and plug-in hybrid electric vehicles;

- Portable electronic devices;

- Medical devices; and

- Space, aeronautical, and defense-related devices.

Developmental Stage

Proof of concept