Through a collaborative project combining experiments and high-fidelity simulations, researchers with the Energy Systems division of the U.S. Department of Energy’s (DOE) Argonne National Laboratory are helping to bring pre-chamber technology and its promise of cleaner and more efficient combustion to heavy-duty vehicles.

Whereas in a conventional combustion system the main chamber is the site of ignition, the new method moves it into a small chamber; i.e., the pre-chamber, connected to the main combustion chamber through a number of orifices. Turbulent flame jets that develop through the orifices quickly spread into the main combustion chamber and significantly accelerate the whole combustion process.

“Extremely dilute mixtures can be burned very fast, thus leading to high thermal efficiency and significantly reduced emissions,” Scarcelli said.

Extremely dilute mixtures can be burned very fast, thus leading to high thermal efficiency and significantly reduced emissions,” Scarcelli said.

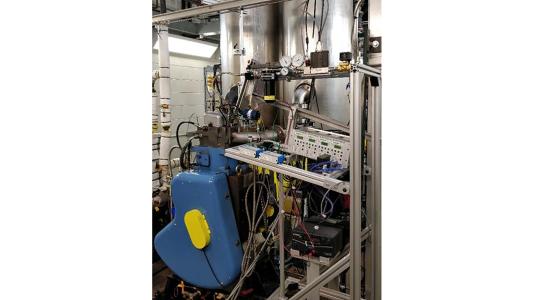

Funded by the Vehicle Technologies Office of the DOE’s Office of Energy Efficiency & Renewable Energy, the project brought together Argonne and three other DOE labs, plus industry partners including an ignition manufacturer and a truck company. Argonne researchers paired their experiments on a single-cylinder, natural gas research engine which is “representative of a medium-duty truck engine,” said Munidhar Biruduganti, a principal engine researcher with Argonne’s CTR, with high-fidelity simulations utilizing the computational solver CONVERGE CFD and high-performance computer clusters Blues and Bebop of the Argonne Leadership Computing Facility.

“At Argonne, we used experiments and simulations together to shed light on important physics during the combustion process and highlight the challenges for this technology,” Scarcelli said. Not only do the simulations reproduce the actual physical processes in an engine during combustion but they also provide other important details, such as mixture formation in the pre-chamber, which cannot be observed in metal engine experiments, he added.

While pre-chamber ignition technology has been in use for several decades in large-bore marine and power generation platforms, it is now finding its way into smaller-scale applications via medium- and heavy-duty trucks, Biruduganti said. “Our findings benefits the global research community and industry, both original equipment manufacturers and Tier I suppliers, by offering unique computational fluid dynamics and design tools to build more efficient medium- and heavy-duty natural gas engines,” he said.