- Method of Printing and Implementing Refractive X-Ray Optical Components (ANL-IN-20-070)

Technology

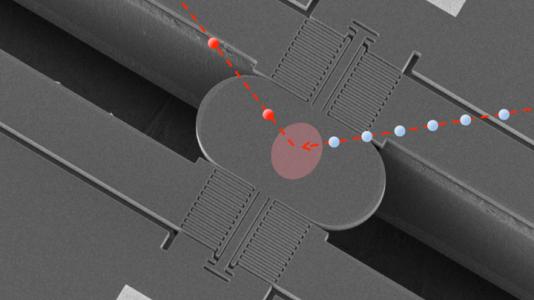

Using high-resolution polymerization lithography, this technology enables rapid and cost-efficient printing of refractive X-ray optics, such as phase correctors and compound refractive lenses (CRLs) with a better-than-100 nm printing resolution. These optics have shown a higher quality and better performance than conventional lenses, such as those commercially available Be CRLs. Supported on the small flat substrates, these lenses can be quickly deployed into an X-ray beam delivery system.

Opportunity & Solution

To fully utilize DOE’s high coherence of the diffraction-limited X-ray sources, there is an urgent need for a giant leap forward in the manufacturing capabilities of X-ray refractive optics that are required for controllable wavefronts in the applications of coherent-based experiment methods. To meet these goals, Argonne National Laboratory researchers have been developing a customizable strategy to manufacture and deploy polymer-based refractive X-ray optics at synchrotron beamlines.

Benefits

- Improve multiple polymerization printing lithography schemes for better lens quality and shape controls.

- Improve the printing resolution to 20-50 nm.

- Scale-up the procedure for high-throughput optics fabrication, aiming at a useful lens array set per one to a few hours.

- Investigate high-energy (>20 kev) and high-coherence applications of printed optics.

- Design commercialization-ready assembly scheme for stand-alone instrument that allows fast optics alignment and flexible operation to meet various experimental requirements at synchrotron beamlines.

- Develop a cost-effective transfocator mechanism for rapid lens exchange and replacement.