Argonne, UMN team confirms benefits of grassland sharing with solar farm

Farmland is prime real estate for installing solar panels because it’s relatively flat. Although some say adding solar panels reduces land available for crops or other uses, scientists are finding that land sharing strategies can serve multiple benefits for energy and food production and the environment.

Working with researchers at the Institute on the Environment at the University of Minnesota (UMN) in St. Paul, scientists at the U.S. Department of Energy’s (DOE) Argonne National Laboratory and National Renewable Energy Laboratory found that restoring native grassland vegetation around solar panels benefits pollinators and other related ecosystem services. The team developed models for 30 Midwestern solar farms and found that native grass plantings at solar farms could increase pollinator habitat quality threefold compared to farmland before solar panels were installed. These improvements aid in insect pollinator conservation and may contribute to pollination services nearby. Researchers also measured the benefits associated with a solar site’s ability to stabilize soil, reduce erosion and store carbon with the native plantings.

The team concluded that land sharing in agricultural areas can be a win-win solution for renewable energy and food production.

UMN researchers study jet noise with Argonne supercomputers

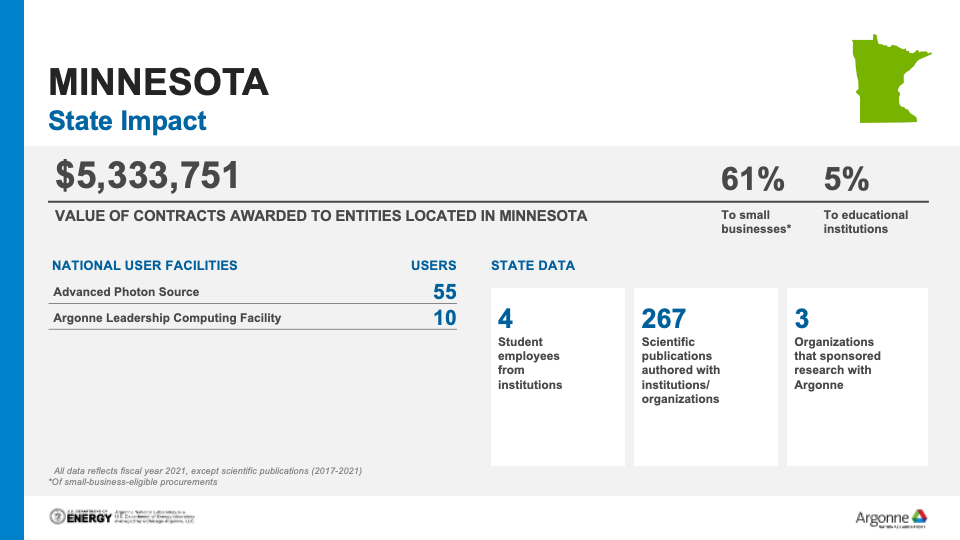

Researchers from the UMN are exploring a path to reducing jet engine noise, using the power of supercomputers at the Argonne Leadership Computing Facility (ALCF), a DOE Office of Science User Facility. Led by Joseph Nichols, a professor in the university’s Aerospace Engineering and Mechanics department, the team performed complex computational fluid dynamics simulations in collaboration with ALCF computational scientist Ramesh Balakrishnan to determine whether jet noise can be lowered by changing the turbulent structures in the exhaust streams of large jet engines.

Argonne’s supercomputers allowed the researchers to simulate fluid motions that would be impossible to see with less powerful computers. The Minnesota team leveraged their simulations to create a novel data-driven method that can be used to predict and understand the aeroacoustics of high-speed jets, which could lead to new engineering designs to reduce the noise produced by jet engines.

UMN biofuels team wins patent for novel ethanol separation process

An Argonne Director’s Discretionary Award was the catalyst UMN researchers needed to bring their biofuel idea to fruition and win a patent for it. Department of Chemistry Professor J. Ilja Siepmann was awarded supercomputing time at the ALCF to learn more about which zeolites work best to chemically extract ethanol from water, an essential step in biofuel production.

Zeolites are porous materials containing various combinations of mainly silicon, aluminum and oxygen and are widely used as chemical sieves and catalysts. The power of Argonne’s supercomputers allowed Dr. Siepmann and his team to test the separation performances of 400 different zeolites over ethanol-water compositions ranging from 0.1% to 40% ethanol by weight. The new ethanol extraction process permits significant energy savings over traditional distillation-based separation, saving in production costs and increasing the net gain in the environmental benefits of biofuels.