UVA researcher teams up with Argonne to improve metal additive manufacturing

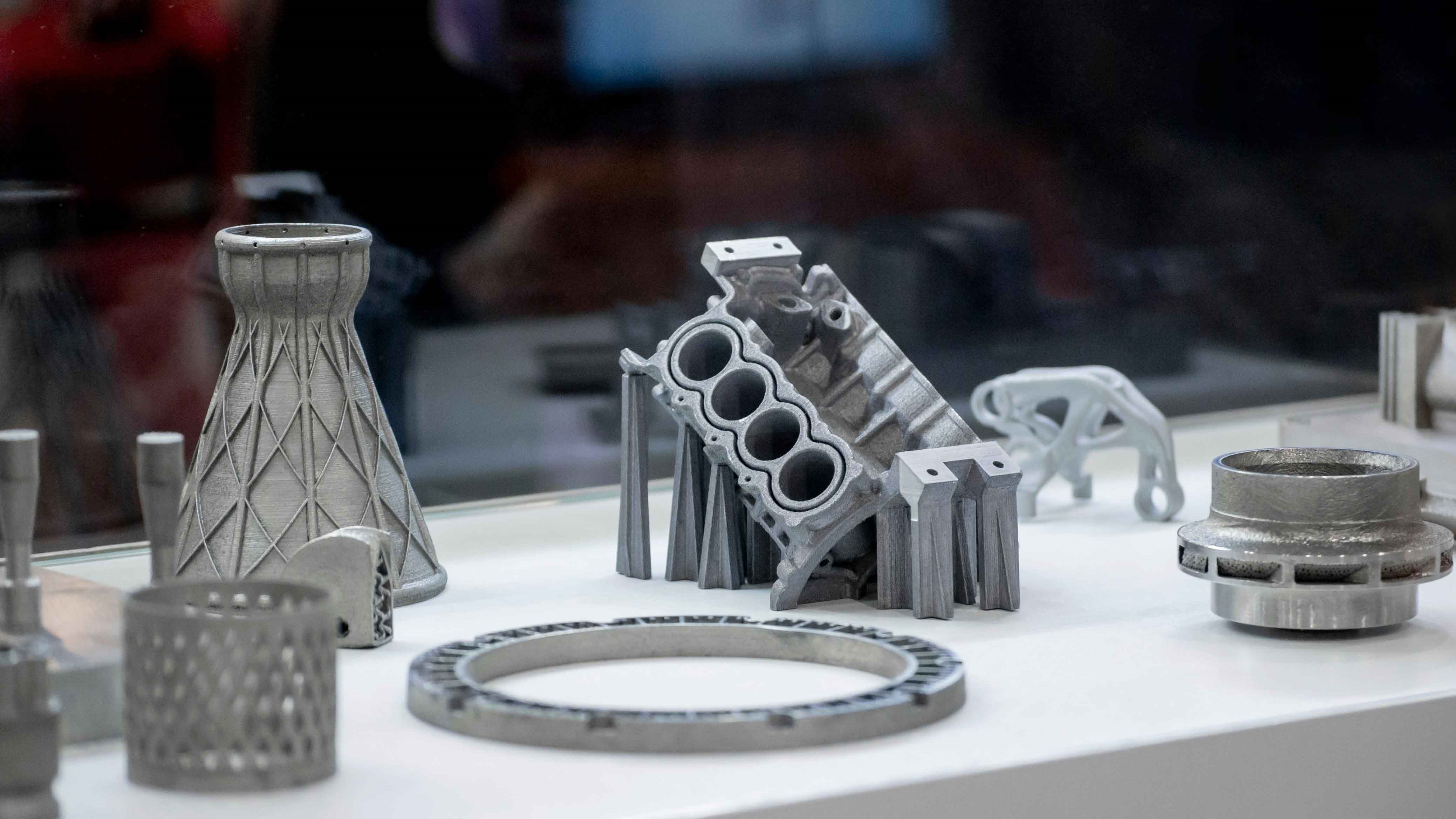

Many industries rely on metal additive manufacturing to rapidly build parts. This process, which involves building parts layer-by-layer using a 3D printer, allows users to build complex metal parts quickly, but structural defects that form during the process have prevented this approach from being widely adopted. A recent study, published by researchers from the University of Virginia and the Department of Energy’s (DOE) Argonne National Laboratory, reveals a new method for detecting and predicting pore defects in 3D printed metals, which could transform the additive manufacturing process.

Tao Sun, an associate professor in Material Science and Engineering at UVA, relied on Argonne’s Advanced Photon Source (APS), a DOE Office of Science User Facility, to generate high-resolution X-ray images of pore generation in dense, metal parts. Sun and his colleagues then used these images, along with thermal images, to develop a machine learning model that predicted where pore defects occurred in 3D printed metals in real time with near-perfect accuracy. This monitoring process can be implemented into commercial additive manufacturing machines to save researchers time when they inspect metal parts for pore defects. The scientists’ ultimate goal is to create a monitoring system that not only detects defects, but also repairs them during the manufacturing process.

Argonne model informs the technology of the winner of a prestigious battery recycling prize

Argonne has a model which informed the technology of Blacksburg, Virginia-based Li Industries. The company subsequently led a winning team in a prestigious battery recycling prize competition. This successful application of the model, called EverBatt, demonstrates its potential to help shape a robust battery recycling industry.

EverBatt is a free, publicly available Excel-based tool. It enables users to directly compare the costs and environmental impacts of battery recycling and other battery supply chain processes. It is designed to inform investment decisions in sustainable, cost-effective recycling infrastructure.

Li Industries developed a “Smart Battery Sorting System.” It uses machine learning, cameras and other sensors to automate sorting and separation of end-of-life lithium-ion batteries. It can sort by battery type and chemical composition. The technology can potentially enable faster, more accurate and lower cost separation relative to traditional, manual sorting processes.

Argonne customized EverBatt for Li Industries. The company used the model to evaluate the sorting system’s potential cost and environmental impacts on recycling supply chains.

The analysis revealed that the overall costs of an automated sorting plant are consistently lower than its manual counterpart. This is due to significantly lower labor costs. It also showed that automated sorting has negligible environmental impacts relative to the overall recycling supply chain.

Argonne, Virginia Tech scientists shed light on the ‘dark universe’

Scientists believe the universe is dominated by “dark matter” — a form of matter that does not emit or absorb light, but can bend it through gravitational interactions. Furthermore, they have observed that the universe is expanding at an accelerating rate due to a mysterious cause they call “dark energy.”

To improve our understanding of these puzzling phenomena, scientists are planning and performing many sky surveys. Creating predictions for those surveys and interpreting their results require state-of-the-art simulations and advanced statistical analysis methods. Together, researchers at Argonne and Virginia Polytechnic Institute and State University (Blacksburg) are developing new methods that combine supercomputer simulations and observations to enable scientific discoveries. The use of such techniques could shed light on the “dark” elements that make up most of our cosmos.

The team’s work is supported by a SciDAC-4 award from the DOEs Scientific Discovery through Advanced Computing program.

Using APS X-rays, Virginia Tech scientists make breakthrough discoveries on how mosquitoes drink

Partnering with scientists at Argonne’s APS, an international team led by researchers at Virginia Tech made a breakthrough discovery about how mosquitoes drink. Using beamlines at the APS, the researchers studied the morphology of mosquitoes’ feeding mechanism. After trapping mosquitoes in the woods near the Argonne lab and sequestering them for 48 hours, the team provided them with a sugar-based feeding solution while tracking their feeding activity.

The APS X-ray images revealed a startling discovery: mosquitoes change how they drink using two pumps in their head. Having an extra pump enables a secondary “burst mode” of feeding that gives the insect more options and allows for multimodal feeding and flexibility.

Because mosquitoes are a public health threat capable of transmitting viruses to humans and other animals, the new findings on how they feed could have larger implications for how scientists address mosquito-borne disease transmission in future research.

The APS is a DOE Office of Science User Facility.

UVA/Argonne team discovers catalyst that improves solar energy harvest for fuel production

Harnessing solar energy to produce fuels involves splitting water molecules into oxygen and hydrogen. The hydrogen produced by the process is stored as fuel, but the catalysts used to split water molecules are too inefficient to make the process practical on a large scale. A recent breakthrough by scientists at Argonne, UVA and other organizations, however, could change that reality.

Researchers produced a catalyst using cobalt and titanium, elements much more abundant in nature than commonly used catalytic materials containing precious metals like iridium or ruthenium. Using synchrotron X-ray scattering and spectroscopy at the APS, the team found that the catalyst’s well-defined surface structure allowed them to see how it evolved during the splitting process and enabled them to accurately evaluate its performance. Using this method, scientists expect to identify even more efficient catalysts.

Also participating in the research are the California Institute of Technology, Lawrence Berkeley National Laboratory and Brookhaven National Laboratory.