A roar of approval rang out at the U.S. Department of Energy’s (DOE’s) Argonne National Laboratory upon the announcement that John B. Goodenough, M. Stanley Whittingham and Akira Yoshino had won the 2019 Nobel Prize in Chemistry. They received this highly desired prize for their major contributions to the invention of the lithium-ion battery, which is a long-standing major focus of research at Argonne.

Today, their invention can be found in portable electronic devices everywhere. This groundbreaking research in the mid-1990’s had a major impact on the direction of the battery program at Argonne. Michael Thackeray, an Argonne Distinguished Fellow in the Chemical Science and Engineering (CSE) division, had worked for Goodenough at Oxford University in 1981-1982. At that time, Thackeray and Goodenough invented a manganese spinel cathode that was cheaper and safer than the cobalt-oxide cathode invented earlier by Goodenough, though it suffered from poorer performance.

The cathode is the positive electrode of the battery, while the anode is the negative. Electrons in the battery flow from the anode to the cathode, creating an electrical current when, for example, a cell phone is being used. Charging the phone relies on power from the electrical outlet, wherein the electrons flow in the opposite direction; from cathode to anode so that it can be used again.

From 1983 to 1994, Thackeray, while at the Council for Scientific and Industrial Research in South Africa, continued to discover and develop new cathode materials for lithium-ion batteries.

Argonne’s battery program: past achievements

Upon Thackeray’s arrival in 1994, Argonne already had in place a large program focused on developing an advanced “molten salt” battery, a much different type of battery than the lithium-ion technology. This battery has an energy storage capability high enough to power electric vehicles and serve as supplementary power for the electric grid during peak-use hours. Its main drawback is that the need to keep the electrolyte salt melted requires battery cell maintenance at a very high temperature, above 750 degrees Fahrenheit. This necessitates a complex and reliable heat management system. By contrast, the lithium-ion battery operates well at temperatures from just below freezing to several tens of degrees above room temperature.

The name, “lithium-ion battery” refers to the lithium ions (an ion forms when an atom or molecule loses or gains one or more electrons) that rock back and forth between the cathode and anode during charge-discharge of the battery. In the cathode during charging, lithium ions exit the structure on their journey to the anode and leave holes, or vacancies, behind. If too many are removed, then these holes weaken the structure, and performance declines.

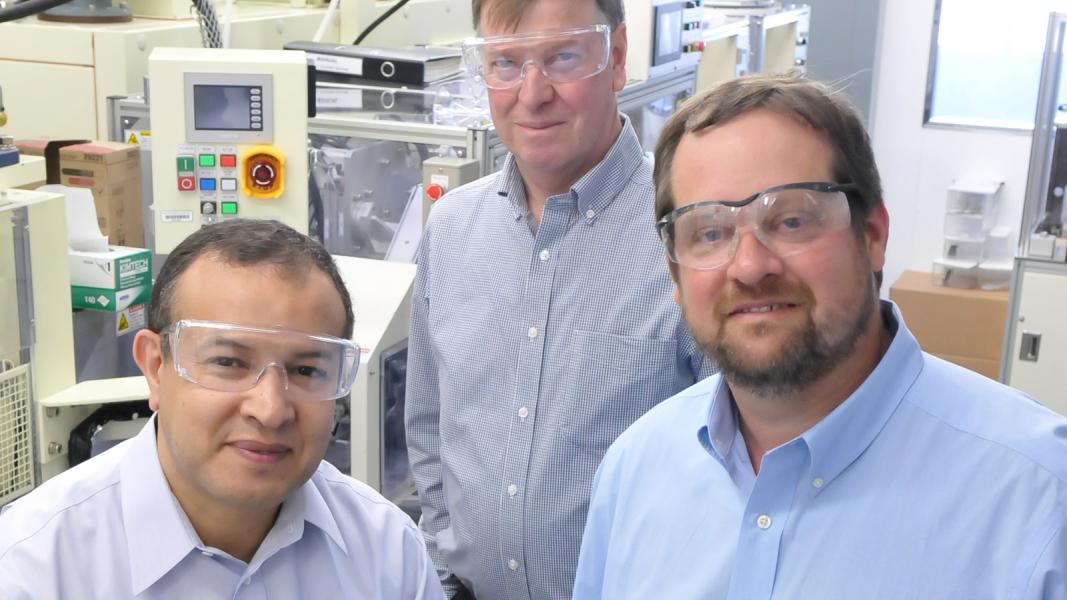

Working in collaboration with other Argonne researchers, Thackeray made a very important discovery — a lithium-rich nickel-manganese-cobalt oxide (known as “NMC”) cathode that provided a noticeable improvement in performance, reliability and safety over the then-current lithium-ion technology. The other Argonne inventors were Christopher Johnson and Khalil Amine, both Argonne Distinguished Fellows in the CSE division. This NMC cathode was a major breakthrough because it furthered the use of lithium-ion batteries in electric vehicles and other applications.

For commercial success, any new battery material must be manufacturable in enormous quantities at reasonable costs. Amine spearheaded the effort to ramp up the NMC synthesis process to the commercial scale. “You must find the exact right temperature, starting chemicals, reaction times and environment — all these have to be on target at low enough cost for commercial application,” said Amine.

In the last decade, Argonne has licensed the NMC technology to materials manufacturers and lithium battery manufacturers worldwide — including General Motors, BASF, LG Chem, General Electric and Toda America. General Motors adopted this technology in the world’s first mass-produced plug-in hybrid electric car, the Chevy Volt, as well as the Chevy Bolt, an all-electric vehicle.

Since the NMC invention, key discoveries in lithium-ion batteries have continued to flow out of the Argonne battery program. One example is the ‘full concentration gradient’ cathode. It has three key ingredients (nickel, manganese and cobalt) that vary in a carefully tailored way within each cathode particle to take full advantage of each ingredient. This led to better energy storage and stability.

Argonne’s battery program today

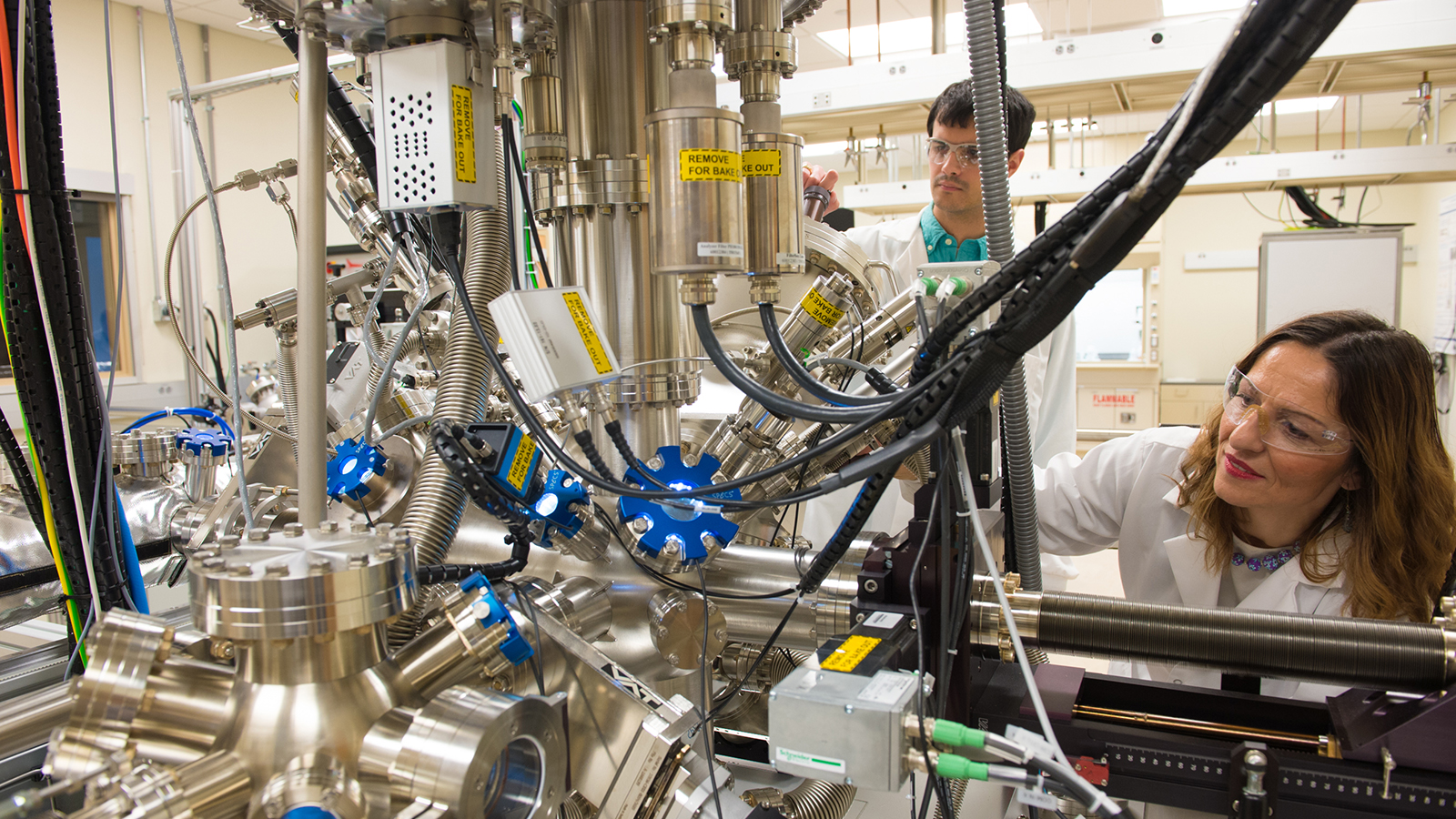

With more than 250 battery technologies available for licensing and thousands of publications in scientific journals, Argonne is a global leader in battery research and development. Today, Argonne and collaborating scientists have a unique collection of world-class facilities for battery research. There is the Argonne Leadership Computing Facility, which has supercomputing capabilities for modeling to predict the behavior of battery materials. Researchers also have access to the Advanced Photon Source, the Center for Nanoscale Materials and the Electrochemical Discovery Laboratory, where they conduct in-depth materials testing. The Argonne Leadership Computing Facility, Advanced Photon Source and the Center for Nanoscale Materials are all DOE Office of Science User Facilities. Researchers from around the world can apply to use these facilities for collaborative research.

Additionally, there is the Cell Analysis, Modeling, and Prototyping facility for engineering prototype electrodes and battery cells. There is also the Electrochemical Analysis and Diagnostics Laboratory for testing the new materials. After standardized testing, researchers can send their cell and electrodes for analysis in Argonne’s Post-Test Facility.

Also available is the Materials Engineering Research Facility (MERF), where researchers develop manufacturing processes that produce new materials or products in large quantities and, in some cases, larger sizes and do it in a way that is cost effective. The MERF work is helping to bridge the gap between materials discovery and use of the new discoveries in new technologies.

Today, Argonne is also the lead laboratory for three award-winning, multi-institutional centers for battery research: the Center for Electrochemical Energy Science (CEES), the Joint Center for Energy Storage Research (JCESR) and the ReCell Center for Lithium Battery Recycling R&D.

The next generation

The 2019 Nobel Prize recognized the truly transformational impact of batteries — as readily apparent by small lithium-ion batteries present in portable electronics everywhere. Drawing upon the early research conducted in the 1970s and 1980s, Argonne contributed in a major way to the initial successful adoption of large lithium-ion batteries for electric vehicles.

“The lithium-ion battery research captures the value of innovative, out-of-the-box thinking for charting society’s future. It is an inspiration and an encouragement to the next-generation innovators who will take energy storage and its applications to new levels of impact,” said George Crabtree, JCESR director.

Researchers at Argonne and elsewhere are now racing to develop the next generation of battery — super-batteries a leap beyond the current lithium-ion. Such batteries will one day lead to a more energy-secure future, highly resilient and efficient electrical grids via the storage of solar and wind energy, and more widespread adoption of electric vehicles and even, possibly, electrical-powered flight.

Original article published on December 9, 2019